Diameter Of Rivets

Description

This section is from the book "Practical Sheet And Plate Metal Work", by Evan A. Atkins. Also available from Amazon: Practical Sheet And Plate Metal Work.

Diameter Of Rivets

With any given thickness of plate, the first thing to determine is the diameter of the rivet which is most suitable for the joint. And, in considering this, we shall see that there are several practical considerations which assist us in arriving at the best size. If the holes are to be punched in the plate we shall find that it is practically impossible to punch holes of less diameter than the thickness of the plate. Even with holes equal in diameter to the thickness of plate, it will be necessary to have a large clearance between the punch and die or else the punch will break, and this arrangement again will give a very much tapered hole. Therefore, in practice, it is not a good plan to punch holes of less diameter than 1¼ times the thickness of the plate.

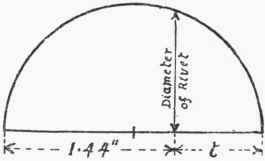

On the other hand, to form a good joint the rivet must not be of too great a diameter, as this will entail a broad lap; and the rivets being set at too great a pitch, consequently it will be difficult to get a perfectly tight joint; and even if properly caulked, changes of temperature would soon cause the joint to open and leak. The difficulty of small holes is, of course, overcome when the holes are drilled; but here again we are met with a practical difficulty, and that is if too small a rivet is chosen a much larger cost is incurred in drilling and riveting on account of the greater number of holes required in the joint. Taking all things into consideration, the common rule of making the diameter of rivet equal to one and a quarter times the square root of the thickness of plate is a good guide to assist us at arriving at a suitable diameter. The rule is conveniently written in this formd = 1.25 √t A very simple way of obtaining the required diameter (for those who cannot readily calculate) is shown in Fig. 333. A line is drawn, and along it a distance of 1.44 in. marked, and then on to this the thickness of plate is added. A semicircle is now described on the whole line, and a perpendicular run up as shown. The length of this line will give the required diameter of rivet. In Fig. 333 the construction is for f in. plate, and it will be seen that the rivet diameter comes out nearly 1 1/16 in. The nearest ordinary size to the calculated or measured dimension will have to be chosen. Thus for a ½ in. plated = 1.2 X √.5 = .84 in. and the nearest stock size to this would be 7/8 in.

Generally, the diameter of rivets to suit particular thicknesses of plates will be:-

Fig. 333.

Plate thickness | ¼ | 3/8 | ½ | 5/8 | ¾ | 7/8 | 1 |

Diameter of rivet ... | 9/16 | ¾ | 7/8 | 15/16 | 1 1/16 | 1 1/8 | l¼ |

Rivets for general work, such as girders, roofing, and ship plating, are usually a little less in diameter than in the above table.

Continue to: