Forms Of Joints

Description

This section is from the book "Practical Sheet And Plate Metal Work", by Evan A. Atkins. Also available from Amazon: Practical Sheet And Plate Metal Work.

Forms Of Joints

There are a multitude of different forms and combina-

Fig. 334.

tions of riveted joints. A few kinds only, however, will be shown - just sufficient to explain the arrangement of the plates. No. (20) shows the ordinary single-riveted lap, and (21) the double-riveted lap with zigzag riveting; (22) explains how three plates can be joined by smithing or thinning the edge of the middle one, and (23) shows a similar arrangement for joining four plates by thinning the corners of the two middle plates. Sections across both joints in each of the last two figures are shown, and by reference to these the formation of the joints should readily be understood.

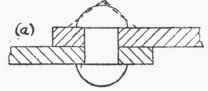

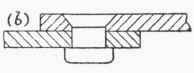

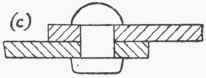

The method of fastening flanged ends in cylindrical and other shaped articles is shown in (24) and (25). And (26) shows how corner or bilge plates may be fixed in, these again being sometimes riveted on the outside instead of the inside, as shown. (27) is a method adopted when two plates need fixing square to each other, the plates being joined by an angle-iron. A form of butt-joint is exhibited in (28), the strap or stiffener being of tee-iron. Sometimes the rivets, instead of being zigzag, are placed opposite each other to form what is known as chain-riveting. Joint (42) explains the method adopted for joining the ends of tubes, a stiffening ring of flat-iron being placed in between the flanges, and (41) shows the same without the ring.

Continue to: