Working Up A Pan

Description

This section is from the book "Practical Sheet And Plate Metal Work", by Evan A. Atkins. Also available from Amazon: Practical Sheet And Plate Metal Work.

Working Up A Pan

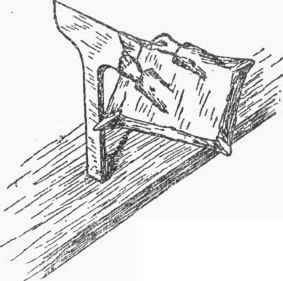

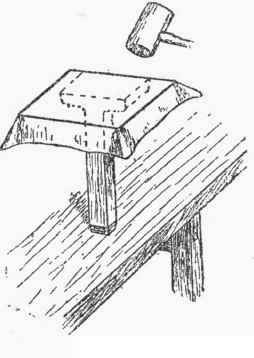

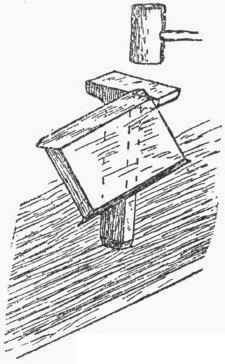

After the four corners of the sheet are cut, the bisecting line of the corner should be placed on the hatchet stake, as shown in Fig. 67, and the sheet bent down on each side. Then the sides and ends should be turned down on a square head or pan stake, as seen in Fig. 68, care being taken that the bottom is kept at its proper size, and that its edges are straight. On the same stake the corner flaps can be closed together (Fig. 69); the greatest care being exercised that

Fig. 67.

Fig. 68.

Fig. 69.

the flaps double up along their centre lines. They should now be slightly bent over on the hatchet stake. The hammering down of the flaps will be done as seen in Fig. 70, and as this is the crucial test of the quality of the sheet metal, and of the operator's skill, some judgment must be exercised in the hammering, or the flap will fracture near the root. To assist in avoiding the breaking of the metal, it should be seen that the flap is fairly well closed together near the root, before proceeding to turn it over. In light sheet metal the mallet must be used carefully, as there is the danger also of the corner of the hatchet or pan stake cutting through the metal. For wiring, the edge of the sheet can be bent over the hatchet stake and the wire slipped in and tucked by the use of the mallet and hammer on the pan stake.

Continue to: