How To Cut Metals

Description

This section is from the book "Welding Theory, Practice, Apparatus And Tests Electric, Thermit And Hot-Flame Processes", by Richard N. Hart. Also available from Amazon: Welding: Theory, Practice, Apparatus And Tests, Electric, Thermit And Hot-Flame Processes.

How To Cut Metals

Besides its use in melting metals for welding, it has recently been found that the oxy-acetylene flame will cut through metals. The importance of this discovery is not yet realized. Wrought-iron and steel plate can be cut through as fast as a carpenter can tear through scantling with a rip-saw; cast iron not so readily. Other metals and alloys, such as aluminum, brass, etc., can also be cut. Jottrand is credited with this discovery.

Cutting is effected by both the melting and the burning of the metal. In the case of iron, the ordinary flame heats it to bright heat, when an extra oxygen cock is turned on. Iron burns with evolution of great heat in the presence of oxygen. At the same time this heat is partly transmitted to the iron in front of the jet, while the jet blows out the iron oxid and molten metal wherever it strikes. When the cutting flame is at its best it entirely oxidizes the iron, blowing out a clean narrow cut. Cutting is a spectacular process, due to the shower of slag sparks that fall from the cut.

While the cutting may be done with the oxygen flame alone, after the iron is red-hot, modern practice uses a preheating torch to which an additional oxygen jet is attached. The torch is the ordinary medium- or low-pressure torch, while the oxygen jet is above 125 pounds. Several firms are selling such torches (see Fig. 36).

The torch is first adjusted to a welding flame, while the cock of the oxygen jet is closed. The operator points the flame at the edge of the metal to be cut. As soon as bright red heat is reached, he moves the flame inward about half an inch and turns on the full oxygen jet which strikes the edge just heated. Meanwhile the flame is heating the new part. For different thicknesses of metal he can use a given oxygen tip, of which each torch has three.

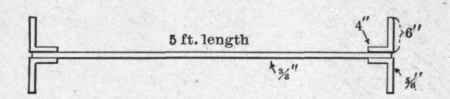

Fig. 58. - Iron girder cut by oxy-acetylene flame.

The rate of cutting varies with the thickness of the plate, and the skill of the operator. Roughly, this flame takes from 1/5 to 1/10 the time in cutting a given section of steel that two men working with a metal saw would take. There are several records of 4-inch plates cut by it, while the companies claim 6 and 8 inches for it.

An exhibition of flame-cutting was given recently by M. Bournonville. During the extension work for the new New York subway approaches to the Williamsburg Bridge it was found necessary to cut through a 3/8-inch I-beam of steel, whose dimensions appear in figure 58. The entire cutting took 21 1/2 minutes. This gives the reader an idea of the efficiency of this process.

This flame should be used to cut any metal that resists the metal saw. Should it fail to oxidize, it would melt its way through. An oxy-acetylene cutter should be an adjunct to every repair shop of any size. It would be found invaluable in cutting away badly wrenched metal work and in cutting and working on parts of any machine, such as an automobile, where a special fixture was to be fastened. For besides its ability to cut, this flame can be made to pierce rivet holes straight through one-inch steel in less than two minutes.

This flame has found its way into the railroad repair shops, one of which uses it to cut away twisted metal on "gondola" coal cars. These cars are light, strong, and durable, and are rapidly displacing the wooden cars. But loss by wreckage is great and a bad wreck of gondolas is a very difficult thing to handle. The cars are often shapeless masses caught together by the force of the impact, and difficult to separate. It has sometimes been necessary to clear the track with dynamite. Two storage tanks and several burners carried on the wrecking train would be of great assistance in such a wreck.

Every auto repair shop of any size will probably have one of these oxy-acetylene outfits in a few years. The same may be said of ordinary machine shops, car shops, boiler shops, etc.

A table of cutting costs has been worked out by the Davis-Bournonville Company, which is here appended. Oxygen is reckoned at three cents a foot, acetylene at one cent, and labor at thirty cents an hour.

Welding Approximate Cost Of Cutting Steel

Number cutting tip | Use welding tip No. | Thickness of steel | Heating jet. Feet of acetylene | Heating jet. Feet of oxygen | Cutting jet. Feet of oxygen | Pressure of oxygen heating jet | Pressure of oxygen cutting jet | Lineal feet cut per hour | Labor . per hour | Total cost per hour | Cost per lineal foot. |

V I | 4 | up to 1/2" | 12 | 15 1/2 | 6o | 14 to 18 lbs. | 125 lbs. | 60 | • 30 | 2.68 | .0447 |

2 | 4 | 1/2" to 1 1/2" | 12 | 15 1/2 | 75 | 14 to 18 lbs. | 125 to 150 | 50 | • 30 | 313 | .0627 |

2 | 5 | 1 1/2" up | 18 | 23 | 95 . | 18 to 22 lbs. | 150 to 175 | 40 | • 30 | 4.02 | .1005 |

Continue to: