I. - By Percolation

Description

This section is from the book "British Homoeopathic Pharmacopoeia", by The British Homoeopathic Society. Also available from Amazon: British Homoeopathic Pharmacopoeia.

I. - By Percolation

This process should be used in all cases of dry plants, roots, seeds, etc, and in the case of such fresh plants, etc, as do not require to be made by the following processes: -

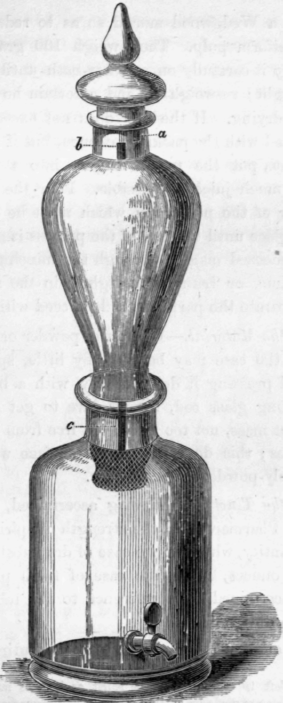

Preparing the Percolator. - Take a York Glass Company's percolator (see Fig. 1), tie over the small end a piece of fine, well-washed book-muslin. Place upon the muslin a layer of about a quarter of an inch of coarsely-powdered green glass,* then a layer of finely-powdered glass half an inch in depth, and lastly, a thin layer of coarsely-granulated glass. The percolator is now ready for receiving the drug.

Preparing the Drug. - 1. If dry, reduce any quantity - for example, 4 ounces by weight - to a moderately fine powder, by bruising in a mortar.

2. If fresh, cut the plant in pieces, pass it through one of Lyon's + tinned-iron mincing machines, and finally of spirit required, or, in the case of fresh plants, one-half to one-fourth, and resting the cork, with the glass rod attached, on the top of the pounded glass, pour the spirit in a gentle stream down the glass rod, so that it may fall on the cork and spread gradually over the surface, without disturbing the pounded glass.

* The green glass should be prepared by pounding in a mortar well-washed and dried common green bottles; the powder should then be washed with distilled water, to get rid of the impalpable powder, and, after being well dried, it should be sorted into three sizes of coarse and fine powder, and granulated glass, by passing through sieves of different degrees of fineness.

+ This machine is recommended because it contains no lead, and admits of the most thorough cleaning.

Fig. 1. - York Glass Company's Percolator.*

* This percolator has been decided on because it is one of the best the Committee are acquainted with. It is entirely made of glass, and is readily cleaned. The chief advantage, however, consists in its ingenious valves, by which the process of percolation can be stopped at any time, and the pound it in a Wedgwood mortar so as to reduce it to a fine and uniform pulp. Then weigh 100 grains of the pulp and dry it carefully on a water-bath until it ceases to lose weight; re-weigh it, and ascertain how much it has lost in drying. If the loss does not exceed 70 per cent., proceed with the packing at once, but if it exceeds 70 per cent., put the moist magma into a press and extract as much juice as possible. Pour the juice into the receiver of the percolator, which must be kept in a cool, dark place until the rest of the process is completed. Pass the squeezed magma through the mincing machine a second time, or triturate it lightly in the mortar, in order to separate the particles, and proceed with packing.

Packing the Material. - Insert the powder or the moist magma, as the case may be, little by little, spreading it evenly, and pressing it down gently with a broad cork fixed to a long glass rod, taking care to get a uniform and compact mass, not too tight, but free from fissures or empty spaces; this done, cover the surface with a thin layer of finely-powdered green glass.

Making the Tincture. - Having ascertained, by reference to the Pharmacopoeia, the strength of spirit required and the quantity, which in the case of dry substances will be 40 fluid ounces, but in the case of fresh plants, etc, must be ascertained by a reference to the tables which follow these directions: -

1. Take one-fourth or one-fifth of the entire quantity substance be left to macerate in the spirit as long as may be necessary. The valves are made by catting a groove half way across the ground surfaces of the percolator and stopper respectively; it hence follows that, when the two grooves are in a straight line, the air can enter and percolation will go on; when, however, they are not opposite to each other, the two compartments will be completely stopped off and rendered air-tight. At a and b in the figure the grooves are shown in the closed position, while at c the valve is open.

2. Remove the glass rod, put in the stopper, and, in the case of dry substances or of fresh plants from which the juice has been previously extracted as above, close the valves as soon as the liquid commences to drop into the receiver. When working with fresh plants, however, from which the juice has not been pressed, leave the valves open until the following quantities of fluid (or as much of those quantities as the density of the magma will allow the displacement of by one-half the entire quantity of spirit), which will be chiefly juice, have passed through into the receiver. For example, if the moist magma has lost between 30 and 40 per cent. in drying, let 1 1/2 fluid ounce drop through; if between 40 and 50 per cent., 2 fluid ounces; if between 50 and 70 per cent., 2 1/2 fluid ounces; then close the valves.

3. In all cases, after the valves are closed, let them remain so for twenty-four hours, and then open them and allow the fluid to percolate into the receiver until no more drops through.

4. Then add another half, fourth, or fifth part of the spirit in the same cautious way that the first was added, and having displaced the saturated spirit held in suspension by the packed material, close the valves, and let them remain closed for at least six hours, and then reopen the valves and proceed as before, repeating the process again and again, adding an equal part of the required quantity of spirit each time until the whole quantity has been poured into the percolator.

5. When the last quantity has ceased to drop through, remove the material from the percolator, and press strongly.

6. Mix the various portions together, and let stand for twenty-four hours, and then filter.

N.B. - The whole amount of tincture obtained after filtration will never be found to equal the quantity of spirit employed, as there is always some loss during the process. This loss occurs partly through the adhesion of the liquid to the utensils used and evaporation, and partly through the impossibility of removing the whole of the tincture from the magma by means of pressure.

It is recommended to add spirit of the suitable strength to the extent of 5 per cent, by volume of the quantity of tincture which should result from the process to compensate the loss from the last-named cause, but no other addition of spirit to the tincture can be made without reducing its proper strength. This liquid should bo poured over the packed magma before pressure.

Continue to: