Filtration Of Sewage And Water Supply. Part 2

Description

This section is from the book "Standard Practical Plumbing", by R. M. Starbuck. Also available from Amazon: Standard practical plumbing.

Filtration Of Sewage And Water Supply. Part 2

The danger, however, is reduced to a minimum when efficient filtration is provided. It may be said that distilled or boiled water is the only absolutely safe water for drinking purposes, though under most conditions neither of these processes is necessary if other proper precautions are taken.

Until recent years, it was generally considered that running water in traveling a few miles became purified through natural causes, such as oxidation, aeration, sedimentation, etc. To a certain extent this is true, but as the water travels, it is constantly taking up new impurities, so that purification in this manner should not be depended upon to any extent.

Owing to the porosity of sand and the consequent existence in it of the bacteria necessary to filtration, this is the material mostly used in filtration plants, especially for large work. That the action of filtration is dependent upon the presence of bacteria, is proved by the fact that whenever substances known to be injurious to them are allowed to enter the water, purification always ceases, either entirely or in part. The sand filter or filter bed, as it is generally known, usually consists of several beds, such as shown in Fig. 236. At the bottom of the bed, in a mass of broken stone and gravel, is laid a drain with open joints, into which the filtered water passes, and through which it is carried into a tight drain and thence to the storage point.

Above the broken stone and gravel is laid a bed of sand, which by the way, should not be of such depth that air may not readily pass through to supply and give life to the bacteria. The impure water is discharged onto the bed and allowed to percolate through the sand, gravel, and stone, this being the action of filtration. As the water passes through and divides between the particles of filtering material, it is open to the action of the bacteria which exist there.

It will be noted that in this method of filtration, there is no pressure upon the water forcing it through the filter, but that it acts entirely by its own gravity or weight. While the amount of water that may be filtered by this means is comparatively small when compared with the output of mechanical filters, it is nevertheless the most thorough in its work of any of the various forms of filters if properly taken care of.

Fig. 236. - Sand Filter Bed.

Experience shows that for clarifying water supplies that are muddy and full of matter held in suspension, mechanical filtration accomplishes better work than sand filtration, and that the latter is the more efficient in the purification of water containing organic substances, such as the water of supplies contaminated by sewage.

Muddy water destroys the action of the sand filter by filling the pores. Therefore the sand filter to be efficient, must be periodically cleaned, which in large work is accomplished by mechanical means.

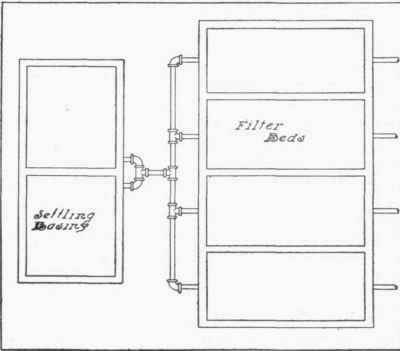

In the use of sand filters, it is excellent practice to first carry the water to be purified into a settling basin or reservoir, where the action of sedimentation may first clear the water of much of its mechanical impurity before it is discharged upon the filter beds. The general arrangement of filter beds and settling basins may be seen in Fig. 237.

The gravity principle is also applied to the domestic filter and to good advantage, producing a filter which comes very much nearer to freeing the water of germ impurities and making it suitable for drinking purposes, than a pressure filter can possibly do.

Fig. 237. - General Arrangement of Filter Beds and Settling Basins.

There are several gravity filters on the market, any one of which does excellent work, so long as it is given proper attention and cleaned at frequent intervals.

The great trouble with filters used for domestic purposes, however, is that they are not properly attended to, under which conditions they may become a menace rather than the safeguard that they are intended to be.

In Fig. 238 is shown a filter working under gravity, it being one of the most popular and efficient forms of the gravity type. Water is delivered to the tank through a ball cock.

From the tank it filters through several porous porcelain tubes filled with bone black. ' From the tubes the filtered water enters a collector which delivers it into a glass globe, from which it may be drawn. Ice coolers of a similar nature are also made, in which the water is filtered, but in such a way that the ice does not come in contact with it, even in its impure state. This same principle is sometimes applied to the filtration of water supplies for hotels, hospitals, restaurants, etc. One method of constructing such a gravity filter is to be seen in Fig. 239, in which the tubes, which are of considerable number, are placed in the filtering tank and the filtered water carried from them to a carbon tank, where it is filtered a second time, then delivered to a storage tank, from which it is carried to the points at which it is to be used.

Fig. 238. - Domestic Gravity Filter.

Fig. 239. - Gravity Filter for Hospitals, Hotels, Restaurants, etc.

The matter of filtration is of great importance also, in the disposal of sewage in country districts or wherever public sewage systems are lacking. Unless disposed of by discharging it upon the surface, sewage in country districts is more often handled by cesspools than by any other method. The common cesspool shown in Fig. 240 is well known to the reader, while the septic cesspool of Fig. 241 may possibly be new to him. The latter while retaining the solid matter that enters it, allows the liquids to leech away into the broken stone or gravel surrounding the cesspool. This particular type of cesspool is excellent when the soil is heavy or damp.

Fig. 240. - The Leeching Cesspool.

Fig. 241. - The Septic Cesspool.

Continue to: