The House Drain. Continued

Description

This section is from the book "Standard Practical Plumbing", by R. M. Starbuck. Also available from Amazon: Standard practical plumbing.

The House Drain. Continued

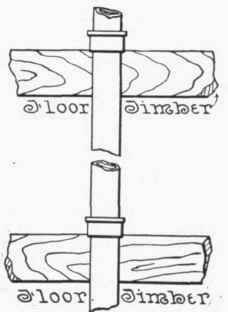

Each line of horizontal pipe that is hung from the basement ceiling or cellar timbers should be supported at each length. Support is provided by means of pipe hangers of wrought iron. These hangers should be made in the form of the letter U, so that each end may be fastened to the timber by screws. Pipe hooks should never be used for this purpose, as they can be fastened only at one end, and lack sufficient rigidity. Great damage is often done to lines of cast-iron pipe by settling, due to their own weight, a danger which may be almost entirely obviated by the proper supporting of the pipe. Another large factor in the weakening of lines of cast-iron pipe, in imperfect joints, etc., is the settling of floors and foundations.

Fig. 79. - Vertical Line of Soil Pipe Supported by Hub at Each Floor.

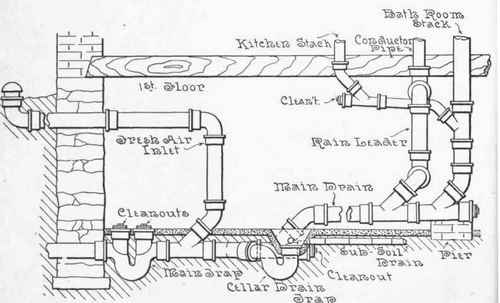

The cellar drainage and subsoil-drainage systems are so closely allied to the main drain that it will be well to consider them in connection with the present subject.

The cellar drain is usually of 4-inch pipe and receives not only the surface drainage of the cellar, but the subsoil drainage also. The drain is formed by a deep well made in the cement cellar bottom, the hub of a half-S cast-iron trap being cemented into the bottom of the well. The surface of the concrete cellar bottom is formed so that from all directions it pitches down toward the cellar drain. Just inside the foundation walls and extending completely around the building a gutter is formed in the cement bottom and carried into the drainage well at its top. By means of the graded bottom and the gutter, all water on the cellar bottom, due to leakage through the walls, leakage of pipes and cocks, etc., may be conducted into the cellar drain.

Beneath the cellar bottom the subsoil drain is laid. This is constructed of porous tile without hub and spigot, and laid with loose, open joints, entirely around the cellar, and from the sides of the cellar into the center of it, wherever necessary. This drain is carried into the drainage well at as low a point as possible, and above the trap. Such a drain is usually employed only where the cellar bottom is damp or wet, and is not usually necessary where the soil is light or sandy.

Fig. 80. - The House Drain and Its Connections.

The drainage well is usually located close to the house drain, the trap connecting into the main through a Y branch. There is danger in the use of the cellar drain, that its trap seal may be broken by evaporation, in which case, if there is no main trap on the house drain, gases and odors from the sewer may enter the cellar or basement through the cellar drain. It is therefore well to provide the trap with a trap screw which may be used to close the opening into the drainage well during periods of drought, when sufficient subsoil water does not enter the trap to maintain a seal. The trap screw may be found of value in some cases, to prevent flooding of the cellar in the event of stoppage of the house drain, or backing up of the sewer. To overcome the danger of loss of seal, in part, at least, it is well to make a deep seal trap by the use of three quarter bends. This provides a very deep seal, which is not easily broken. Such a trap should not be used, however, on any drain carrying other than clear water.

Fig. 81. - The House Drain and Its Connections.

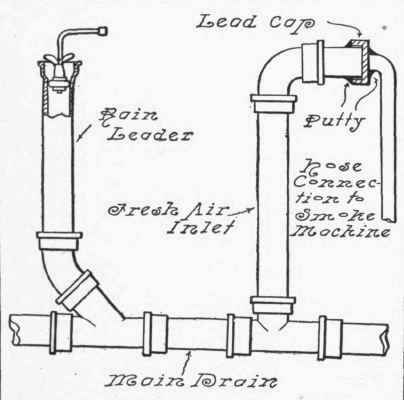

Fig. 80 shows the house drain of a system provided with main trap, and Fig. 81 the house drain of a system which is not thus provided. In each illustration are shown the connections of the cellar drain and subsoil drain, rain leaders, and soil and waste branches.

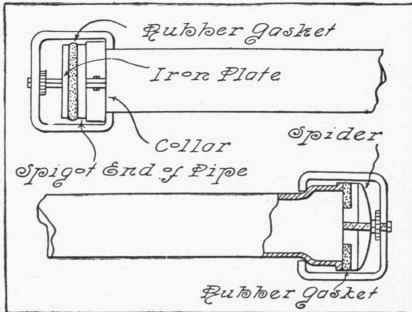

Fig. 82 shows some features of the testing of the house drain and its connections. In making the water or the smoke test, all openings must be closed before the test can be made, as shown in this illustration. Water is generally admitted, in the water test, through a specially constructed testing plug, which is often placed in the fresh-air inlet opening, owing to its convenience to the water connection. Besides the regular testing plugs and the plug with the water connection, a double testing plug, such as shown in Fig. 82, is generally needed, and a trap-testing plug also. The latter is shown in Fig. 83. A sectional view of the common testing plug is shown in Fig. 84, and a sectional view of the double testing plug in Fig. 85. Another very desirable form of testing plug, capable of holding very heavy pressures is illustrated in Fig. 86.

Fig. 82. - The Soil Piping in Readiness for the Water Test.

Fig. 83. - Testing Plug for Running Trap.

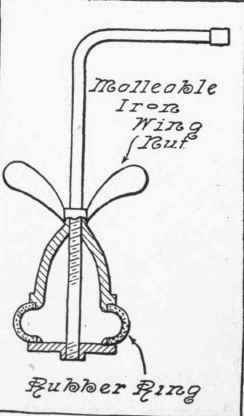

Fig. 84. - Testing Plug.

The single testing plug of Fig. 84 operates by the expansion, against the sides of the pipe, of a heavy rubber ring, which is expanded by being compressed between an iron plate and a wing nut working on a screw. The operation of the double testing plug is as follows: The hollow piece F connects the plug D and the plug B rigidly, and inside of it the rod G works. When the wheel A is turned against the nut E, it expands the plug B, and the plug D is expanded without disturbing the other plug, by turning up the nut C.

Fig. 85. - The Double Testing Plug.

Fig. 86. - Special Testing Plugs.

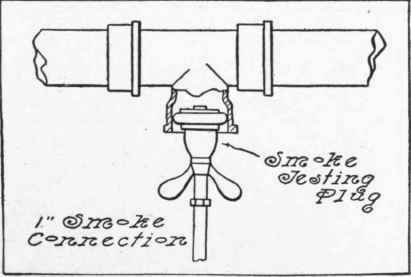

Fig. 87. - Smoke Testing Plug.

Figs. 87 and 88 show methods used in giving the smoke test. For the stopping of openings, ordinary testing plugs may be used. In admitting smoke to the system, however, the method shown in Fig. 88 is generally used. Smoke-testing plugs which admit smoke through them, such as in Fig. 87, are also very handy for this purpose.

Fig. 88. - Plumbing under Smoke Test.

In "Modern Plumbing Illustrated," * by the author of this work, the subjects of water, air, peppermint and smoke tests are taken up very comprehensively, in all their details, in connection with both large and small work.

*"Modern Plumbing Illustrated" by R. M. Starbuck is published by The Norman W. Henley Publishing Co., 132 Nassau Street, New York. Price $4.00.

Continue to: