Bond In Brickwork. Part 3

Description

This section is from the book "A Treatise On Architecture And Building Construction Vol2: Masonry. Carpentry. Joinery", by The Colliery Engineer Co. Also available from Amazon: A Treatise On Architecture And Building Construction.

Bond In Brickwork. Part 3

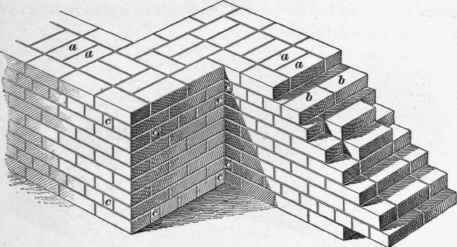

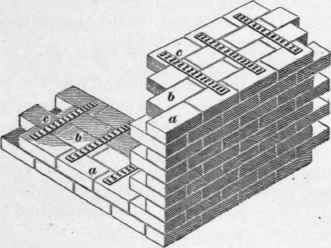

213. Garden Or Running Bond

Garden Or Running Bond. The bond most generally used in this country is shown in Fig. 79. This method, which enables the bricklayer to build a larger amount of wall in a given time than can be accomplished by the use of either the English or Flemish bond, is sometimes called American bond. It consists in laying from five to seven courses in height as stretchers, bonding with a row of headers at regular intervals. The longitudinal lap is secured by closers c, c; the heading course in the heart of the wall is shown at a, a, being placed immediately over the heading course b, b exposed on the face. This is known as garden or running bond. Its principal defect is that the wall is practically composed of a series of 4-inch slices from 12 1/2 to 17 1/2 inches in height, which have no transverse bond other than the mortar, under ordinary circumstances. It fulfils the requirements, however, if every joint throughout the body of the wall is well filled with good mortar, the vertical joints being well rammed with the edge of the trowel.

Fig. 79.

The New York building law requires that every sixth course shall be a heading course; that is, that five courses of stretchers shall come between two courses of headers, as shown on Fig. 79.

For factory and warehouse purposes, where heavy weights come on the wall, it is better to have every fourth course a* header course, thus giving three courses of stretchers between the header courses.

214. Bonding Face Brick

Bonding Face Brick. When face or pressed brick are used for the exterior facing of a brick wall, it detracts from the uniform appearance of the brickwork if the bonding headers appear on the exterior face of the wall. There are several ways of avoiding this difficulty; either by cutting the face brick and the rough brick, or by using steel wire ties to bond the brick together. If no tie or bond were used, the whole 4 inches of brickwork on the face of the wall would have no other connection with the rest of the brick than that given by the adhesion of the mortar, and indeed might be pushed away bodily from the rough brick.

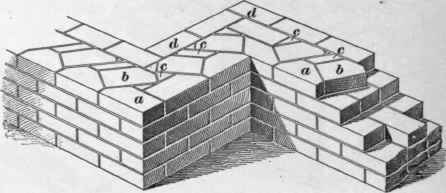

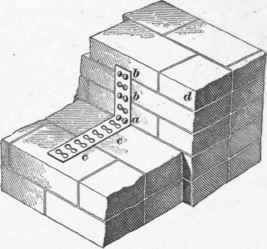

215. Fig. 80 shows a 12-inch wall with the face brick bonded to the common brick by what is known as diagonal, or herring-bone, bond. At a is shown the front brick cut at the angles; at b, the bonding brick laid diagonally; at c, the different shaped bats laid to form the closers of the bond brick; and at d, the inside course of stretchers. It is customary to lay an inside course of headers immediately over the course shown in the Figure.

Fig. 80.

The New York building laws require that "where walls are faced with brick in running bond, every sixth course shall be bonded into the backing by cutting the corners of the face brick, and putting in diagonal headers behind (as shown in Fig. 80), or by splitting the face brick in half and backing the same with a continuous row of headers."

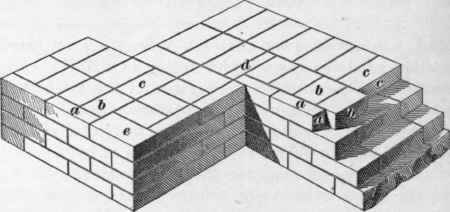

This last method is shown on Fig. 81. The face brick, cut lengthwise, are shown at a. At b, are the three-quarter bats bonding in back of the face brick. The whole brick c bonds on the inside of the wall d, the closer closing up the angle, and e is the whole face brick on the corner of the wall.

Fig. 81.

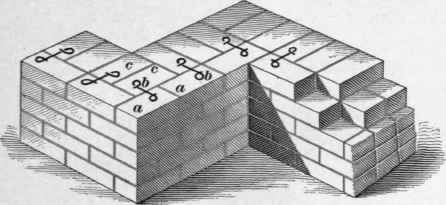

216. Fig. 82 shows the method of bonding in face brick with steel or galvanized iron wire. These wire bonders are twisted at the ends, as shown, to get a better bond, and are laid in every sixth course of brick. The principal objection to the use of steel or iron bonders is the danger of rust, although by the time their efficiency has been destroyed by the action of rust, the mortar used should have hardened sufficiently to keep the face brick in place.

Fig. 82.

A still more modern method of tying front brick to the common brick in the rear of the wall, is by use of perforated steel ties from 3/32 to 1/8 of an inch thick, and having about half the metal punched out. The brick may be brought down to a very close joint, and the clinching spaces make a very firm and satisfactory binder. Fig. 83 shows the application of these bonding strips. Here a is the pressed brick facing b, the common brick in the rear of the wall, and c, the perforated steel ties bonding the pressed brick back to the common brick. The same tie can be used for tying new work to old where walls require lining up to increase their strength. The tie is bent near the middle, as shown at a in Fig. 84, and nailed to the old wall with pointed wrought-iron nails, shown at b, having large flat heads made for the purpose and of sufficient size to make a firm connection for the new courses c. This method avoids the cutting in the old wall d to get in cross-headers, which, at best, must hold very imperfectly after the inevitable shrinkage which comes to all new brickwork.

Fig. 83.

Fig. 84.

Continue to: