Baths

Description

This section is from the book "A Treatise On Architecture And Building Construction Vol4: Plumbing And Gas-Fitting, Heating And Ventilation, Painting And Decorating, Estimating And Calculating Quantities", by The Colliery Engineer Co. Also available from Amazon: A Treatise On Architecture And Building Construction.

Baths

13. The sloping end of a bath tub is called the head, and the vertical end is the foot. Tubs are made in three general styles, the ordinary, French, and Roman, the difference being in the shape.

The ordinary style has a round bottom, with sloping head and vertical foot.

The French style has a flat bottom and flat parallel sides, with rounded corners. The head slopes, and the foot is vertical.

The Roman style is rectangular, the sides, bottom, and ends being flat, with round corners. Both ends and sides are nearly vertical.

The ordinary style requires the least water, but the bottom being semicircular in form, is of inconvenient shape to stand upon.

The French tub affords more room for the bather, but requires more water.

The Roman bath gives most room for the bather. It is designed chiefly to overcome the unbalanced appearance which the other forms present when fitted up elsewhere than in a corner. In this style the faucets are nearly always located outside the tub, and the hot and cold water enters through a single opening. The interior space is thus clear from all obstructions or projections upon which the bather might be injured.

14. The cheapest grade of baths are those made of wood and lined with zinc or tinned copper. Such baths are encased with wood finishings and have a special top made to fit the bath and the position in which it is placed.

Open copper-lined and aluminum-lined baths are clad with a steel or indurated fiber casing, supported on four cast-iron feet, and have the top rim 3 or 4 inches wide all around, attached to the bath.

A sheet of non-conducting material, such as asbestos, is put between the lining and metallic casing. The tin coating soon wears off, and exposes the copper. A harder and more durable coating is secured by nickel plating.

Bath tubs are also made of cast iron, and are used with or without protective coatings. The best grades of iron tubs are coated with porcelain enamel.

The finest grades of bath tubs are made of porcelain, or of a fine fireclay body with a heavy porcelain enamel. They are finished white, or are decorated to any degree desired. Iron and porcelain tubs are usually supported by detachable feet.

The waste pipe is always connected to the bottom of the tub, and should be provided with a strainer to prevent the passage of soap, rags, etc. into the trap.

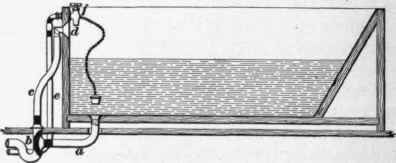

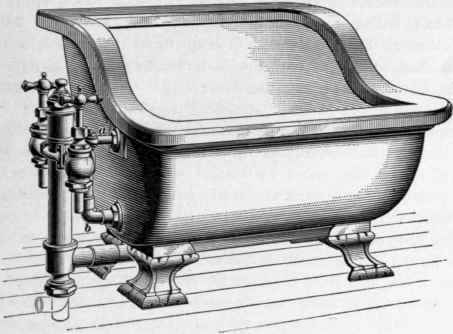

Fig. ll.

A common form of copper-lined wooden tub is shown in Fig. 11. The bath empties through the l 1/2-inch waste pipe a, through the 1 1/2-inch half-S trap b, into the drainage system. A 1 1/4-inch lead overflow pipe c connects the copper overflow pipe horn d to the trap. A 5/8-inch or 3/4-inch lead pipe c supplies the bath with water through the bath cock f.

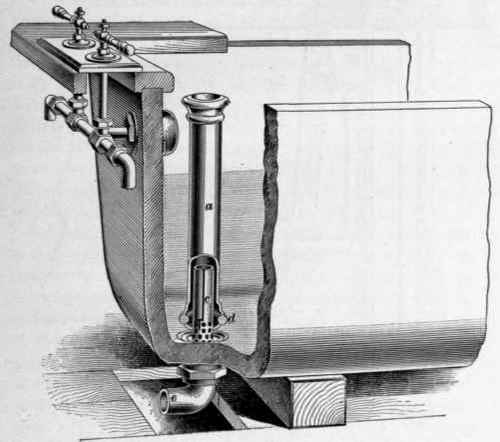

15. Standing overflow and waste pipes are frequently used, as shown in Fig. 12. The overflowing water passes over the top of the standing tube a, and when the tub is to be emptied, the tube is pulled upwards, thus uncovering the perforations at the bottom of the inner tube c, as shown. The outer tube is provided with a rubber ring d, which makes a water-tight joint with the seat when it is dropped down upon the bottom. A bent coupling c is shown attached to the waste outlet. If desired, a straight coupling may be used.

Fig. 12.

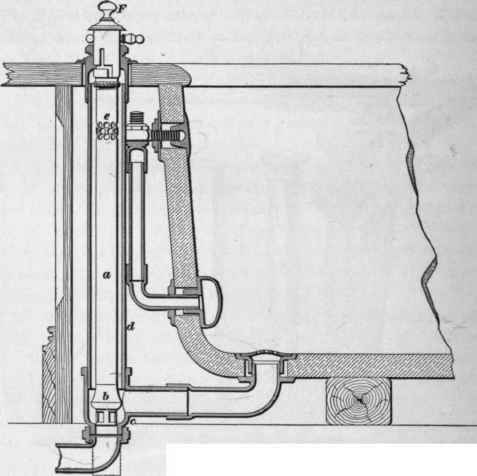

16. A better combination of waste and overflow is shown in Fig. 13. The tube a is provided with a rubber ring b, which shuts down water-tight upon the seat c. The water rises between the tubes a and d to the same height that it does in the tub, until it reaches the perforations e; it overflows through these and passes down the interior of a to the waste pipe. . The inner tube is provided with a handle F having a suitable slot and catch by which it can be lifted and suspended, as shown.

Fig. 13.

These combined waste and overflow devices are adapted to all kinds of bath tubs, whether of wood, metal, or porcelain.

17. The hot and cold water may enter the bath through separate faucets, but are, however, generally delivered to the bath through a single bath cock composed of the hot and the cold shut-off valves joined together into one discharge nozzle. Such a fixture is known as a combination bath cock; it is usually nickel plated. The valves of the cock may be inside or outside the bath. Ground key cocks are seldom used as bath cocks. Fuller and compression valves are mostly used.

The faucets which are used to control the water supply are of two kinds. Plug cocks are used only on very low pressure work; compression cocks are mostly used. The hot and cold water faucets are commonly made in one piece, with a single discharge nozzle.

In the best grades of fittings, angle valves with brass screw-joint connections are used, and they are arranged to deliver water into the tub through the same nozzle, which should enter near the bottom of the tub if it is especially desirable that the water should fill the tub quietly. All the valves and pipes are thus located outside of the tub, and the whole interior space is free of obstructions.

Sometimes the hot and cold water faucets are connected to deliver into the outer shell of the standing waste, so as to supply the tub through the waste-pipe strainer. This is a bad plan, because when the tub is emptied the water passes out first and all soap or refuse goes last. This tends to lodge in the waste pipe, and it will be washed back into the tub, if the fresh water is introduced in that way. In buildings where there is a liability of the water supply being shut off while a bath is in use, the water should enter the bath at a point above the overflow openings. This will prevent it from being siphoned back into the water pipes.

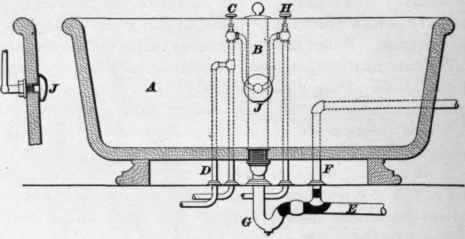

18. Fig. 14 shows the arrangement of the connections to a Roman porcelain bath A. The standing waste B and the supply faucets C and H are placed at the side of the tub, between it and the wall. The mingled hot and cold water enters through the single nozzle J. C is the hot-water faucet, D is the hot-water circulation pipe, E the waste pipe, G the trap, F the trap vent, and H the cold-water faucet. The standing waste B is shown in section in Fig. 13.

19. Metal and porcelain tubs are made with two styles of rim, called plain or roll. A plain rim is shown in Fig. 13, and a roll rim in Fig. 14.

Fig. 14.

Bath tubs which are to be cased in are usually set on a copper or lead base. Those which are to be left open are generally set upon marble safes or upon a floor of some impervious material. Marble safes are usually dished out to a depth of 1/4 or 3/8 of an inch, and have a brass strainer connection to a waste pipe. Tubs should always be set with a small inclination, so that the water will drain properly towards the waste strainer.

The sizes of copper bath tubs range from 4 1/2 to 6 feet long, 24 to 26 inches wide, and 20 to 22 inches deep. Iron bath tubs are usually about 19 inches deep. Porcelain baths are wider, being usually 30 inches at the head and 24 inches at the foot, and are about 22 inches deep. They are quite heavy, a tub 5 1/2 feet long weighing about 600 pounds.

20. Sitz, or seat baths (see Fig. 15) are usually of smaller dimensions, being from 24 inches to 27 inches long, 22 inches wide, and 12 inches to 17 inches high at the front edge, when set up. The back is usually 6 inches, or more, higher than the front.

The sitz bath is fitted up with hot and cold water and waste connections in a manner similar to those shown in Figs. 13 and 14. The hot and cold water valves and the stand pipe are rigidly secured to the side of the bath by a brace a. The hot and cold water mixes and enters near the bottom by the tube b.

Fig. 15.

21. Foot baths are of about the same dimensions as seat baths; some, however, are only 17 inches by 19 inches and 10 inches deep. Seat and foot baths are constructed of the same materials, and are connected to the waste pipes in the same way, and are provided with the same fittings as the full-size baths.

Continue to: