Development Of Patterns For A Hipped Skylight. Part 4

Description

This section is from the book "Cyclopedia Of Architecture, Carpentry, And Building", by James C. et al. Also available from Amazon: Cyclopedia Of Architecture, Carpentry And Building.

Development Of Patterns For A Hipped Skylight. Part 4

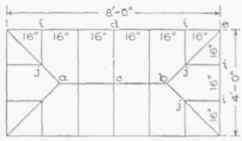

Fig 186.

Rule 1. To obtain the length of the ridge bar in a skylight without a ventilator, as in Fig. 186, deduct the short side of the frame or curb from the long side.

Example: In Fig. 186, take 8 feet (long side of frame) - 4 feet (short side of frame) = 4 feet (length of ridge bar a b).

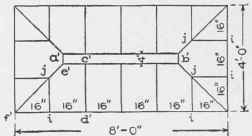

Rule 2. To find the length of the ventilator in a skylight deduct the short side of the frame from the long side and add the width of the desired ventilator (in this case 4 inches, as shown in Fig. 187).

Example: In Figure 187 take 8 feet (long side of frame) - 4 feet (short side of frame) = 4 feet. 4 feet + 4 inches (width of inside ventilator) = 4 feet 4 inches, (length of inside ventilator a' b'). To find the size of the outside ventilator h l and hood m p in Fig. 178 simply add twice the distance a b and a c respectively to the above size, 4 inches, and 4 feet 4 inches, which will give the widths and lengths of the outside vent and hood.

Rule 3. To find the lengths of either common or hip bar (in any size skylight) deduct the width of the ventilator, if any, from the length of the shortest side of frame and divide the remainder by two. Apply the length thus obtained on the base line of its respective triangle for common or hip bars and determine the true lengths of the desired bars, from the hypothenuse.

Example: As no ventilator is shown in Fig. 186, there will be nothing to deduct for it, and the operation is as follows: 4 feet (shortest side of frame)/ 2 = 2 feet. We have now the length with which to proceed to the triangle for common and hip bars. Thus the length of the common bar c d will be equal to twice the amount of A O in Fig. 184, while the length of the hip bar b c in Fig. 186, will be equal to twice the amount of B O in Fig. 185. Referring to Figs. 186 and 187 the jack bars i j are spaced 16 inches, therefore, the length of the jack for 12 inches will equal A O in Fig. 184, and 4 inches equal to 4o O; both of which are added together for the full length.

Fig. 187.

THE "NASSAUER HAUS" IN NURNBERG, GERMANY.

Built at the End of the Thirteenth Century. Railing of Gallery underneath Red-Tiled Roof is Decorated with Coats of Arms. In the Niche over the Fountain at the Lower Right, is a Statue of King Adolf von Nassau.

TERRACE OF HOUSE AT MONTECITO, CALIFORNIA Myron Hunt & Elmer Grey, Architects, Los Angeles, Cal.

For Perspective View of Building, See Page 202; Basement, First, and Second Floor Shown on Page 202.

The lengths of the common and hip bars will be shorter in Fig. 187 because a ventilator has been used, while in Fig. 186 a ridge bar was employed. To obtain the lengths of the common and hip bars in Fig. 187 use Rule 3: 18 inches length of short side - 4 inches (width of inside ventilator) 44 inches; and 44 inches/ 2 = 22 inches or 1 foot 10 inches. Then the length of the common bar c' d' measured with a rule will be equal to A O in Fig. 184 and 10° O added together, and the length of the hip bar c' f' in Fig. 187 will be equal to B O in Fig. 185 and 10x O added together. Use the same method where fractional parts of an inch occur. In laying out the patterns according to these measurements use the cuts shown in Figs. 178, 179, 180, and 181, being careful to measure from the arrowpoints shown on each pattern.

It will be noticed in Fig. 178 we always measure on line 4 in the patterns for the hip, common, and jack bars. This is done because the line 4 in the profiles E and E4 come directly on the slant line of the triangles which were traced to Figs. 184 and 185 and from which the true lengths were obtained. Where a curb might be used, as shown in Fig. 188, which would bring the bottom line of the bar 1 1/2 inches toward the inside of the frame b, all around, then instead of using the size of 4 x 8 feet as the basis of measurements deduct 3 inches on each side, making the basis of measurements 3 ft. 9 inches x 7 ft. 9 inches, and proceed as explained above.

Fig. 188.

Roofing

A good metal covering on a roof is as important as a good foundation. There are various materials used for this purpose such as terne plate or what is commonly called roofing tin. The rigid body, or the base of roofing tin, consists of thin sheets of steel (black plates) that are coated with an alloy of tin and lead. Where a first-class job is desired soft and cold rolled copper should be used. The soft copper is generally used for cap flashing and allows itself to be dressed down well after the base flashing is in position. The cold-rolled or hard copper is used for the roof coverings. In some cases galvanized sheet iron or steel is employed. No matter whether tin, galvanized iron, or copper is employed the method of construction is the same, and will be explained as we proceed.

Another form of roofing is known as corrugated iron roofing, which consists of black or galvanized sheets, corrugated so as to secure strength and stiffness. Roofs having less than one-third pitch should be covered by what is known as flat-seam roofing, and should be covered (when tin or copper is used) with sheets 10 x 14 inches in size rather than with sheets 14 x 20 inches, because the larger number of seams stiffens the surface and prevents the rattling of the tin in stormy weather. Steep roofs should be covered by what is known as standing-seam roofing made from 14" x 20" tin or from 20" x 28". Before any metal is placed on a roof the roofer should see that the sheathing boards are well seasoned, dry and free from knots and nailed close together. Before laying the tin plate a good building paper, free from acid, should be laid on the sheathing, or the tin plate should be painted on the underside before laying. Corrugated iron is used for roofs and sides of buildings. It is usually laid directly upon the purlins in roofs, and held in place by means of clips of hoop iron, which encircle the purlins and are riveted to the corrugated iron about 12 inches apart. The method of constructing flat and double-seam roofing, also corrugated iron coverings, will be explained as we proceed.

Continue to: