2. The High-Pressure Hot Water Heating System

Description

This section is from the book "The Principles And Practice Of Modern House-Construction", by G. Lister Sutcliffe. Also available from Amazon: How Your House Works: A Visual Guide to Understanding & Maintaining Your Home.

2. The High-Pressure Hot Water Heating System

In my description of the low-pressure system of heating by hot water, it was pointed out that the apparatus was in communication with the open air, so that no pressure, except that due to the height of the water in the apparatus, was possible. If, however, the apparatus be made of sufficient strength, it may be closed entirely, and in that case temperatures may be attained which cannot be reached with the low-pressure system. It is quite usual for a high-pressure system to show a temperature of 300o to 350° Fahr. on the pipe-coils, whereas with low-pressure coils a temperature of about 150°-180° is usually not exceeded.

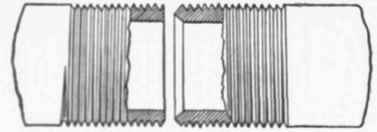

Mr. A. M. perkins was the inventor of the high-pressure system about the year 1837, so that it is by no means a novelty to-day. The system consists in the use of very strong wrought-iron pipes, having an internal diameter of about ⅞ inch, and an external diameter of 15/16 inch. These pipes are joined together in the manner shown in Fig. 544; the end of one pipe is tapered both inside and outside to a sharp edge, and the end of the other is left square, and one end is threaded with a right-hand thread and the other with a left-hand thread. The two pipes are connected with a right-and-left-threaded socket, no jointing material of any kind being used; the sharp edge of the one pipe is merely forced against the flat face of the other. The pipe is continuous throughout, and is coiled upon itself to give the proper heating-surface in the furnace.

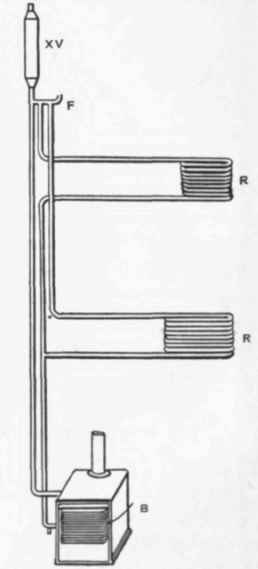

The general arrangement of the system is shown in Fig. 545. The coil B is placed inside the furnace, and the coils r r are the radiating media; these are somewhat unsightly, and must be inclosed in ornamental cases if used inside rooms. At the top of the house is fixed a filling-pipe v, winch can be sealed off with a proper plug, and above that is an air or expansion-vessel XV, consisting anally of a piece of pipe of rather larger diameter. No air-cocks are required, and no cistern tor tilling the apparatus. It is merely filled in the first place through the filling-pipe F; the stopper is then fixed, and the apparatus may be started. As soon as the fire in the furnace is lighted, the- water begins to-expand, and compresses the air contained in the expansion-vessel. A very rapid circulation is set up throughout the apparatus, which will of course continue so long as the tire in the furnace is attended to. The -smallness of the pipes renders it possible to put them in places where the large cast-iron pipes of the low-pressure system could not possibly be fixed, and floor-channels of very small size will accommodate quite a large number of pipees. The rapidity of the circulation has also another advantage: it enables the pipes to be carried below the doorways, that is, to dip down in a way quite imposible with the low-pressure system. With the latter, the great objection to a "dip" is that the air will become locked in the higher part of the pipe, but this cannot occur with the high-pressure system, as it is pumped quite full of water and then sealed up; for the same reason no dirt can get in, and no extra water needs to be added to make up for evaporation, as no evaporation can occur. The pipes are often run along the whole length or width of a room at the back of the skirting-board, which is then replaced by a metal graiting, allowing the exit of the heated air; or a coil is placed inside a special case with hit-and-miss gratings, and an opening to the external air, as already explained in connection with low-pressure radiators. There is some little difficulty about shutting off a portion of the system, and judgment needs to be exercised.

Fig 544 - Method of Joining Pipes for Hlgh-pressure Heating.

Fig. 545. - View of High-preaaure Hot-water Apparatua. B. boiler; F, filling pipe; XV, ex-panaioa-reMel; R R, radiators.

The pipes, being of such small diameter, are of very small capacity, and the volume of water can, therefore, be readily heated to a high temperature in a very short time; this is in many cases a distinct advantage, but in a house it is not of much consequence, as the fire in a domestic apparatus is rarely allowed to go out during the whole of the cold season.

The small volume of water in the pipes renders the system particularly liable to fluctuations of temperature, due to the varying condition of the fire in the stove, and this needs somewhat more careful attention than that of an ordinary low-pressure apparatus. Again, if stop-valves are used to shut off part of the apparatus the fire must be regulated to suit, otherwise the proportion of pipe in the stove will become excessive for the length used as a radiating medium, and the exposed pipe will therefore become too hot The usual proportion of pipe in the stove to the exposed part, is about as 1 to 10 for ordinary heating work. Of course, in the case of a public hall, where all or none of the heating would be required, the problem is simple, but where, as in the case of a house, the requirements fluctuate, the problem becomes somewhat more complicated. Many private houses, however, are satisfactorily heated by this system.

Continue to: