Chapter VIII. Hoods

Description

This section is from the book "Practical Sheet And Plate Metal Work", by Evan A. Atkins. Also available from Amazon: Practical Sheet And Plate Metal Work.

Chapter VIII. Hoods

An iron plate worker, whitesmith, or blacksmith may, some time or other, want to make a hood for a smithy hearth or some other purpose. We will therefore describe the setting-out for one or two typical cases.

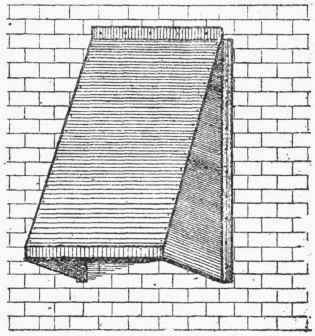

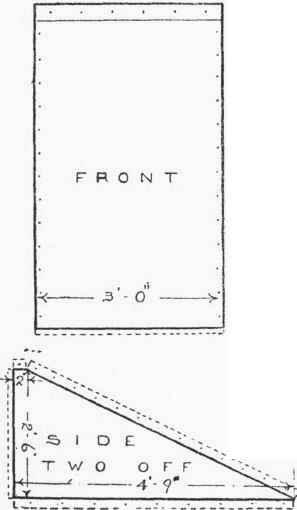

Hoods are made in a variety of forms, depending upon the size, position, and shape of the hearth or other object to be covered. A common kind of hood, and the ones that we shall deal with in this article, are those that fit against a wall. A hood of this description, with flat front and sides, is shown in Fig. 42. It is constructed in three pieces, two sides and front. To make the describing of the setting-out plainer, it will be as well to fix some dimensions to the hood. Suppose them to be as follows: - Height 4 ft. 9 in., width 3 ft., depth 2 ft. 6 in., and turn down in front 2 in. The side can be marked out as shown in

Fig. 42.

Fig. 43. Two lines are drawn square to each other, the one being made 4 ft. 9 in. and the other 2 ft. 6 in. A line 2 in. long is now drawn square to the end of the 2 ft. 6 in. line, and the end of this joined to the end of the height line. The slant line obtained will, of course, give the length of the front plate.

From the well-known property of the right-angle triangle: - "The square of the hypothenuse is equal to the sum of the the squares of the two sides," the slant height, or length of front, can be calculated thus: -

(55)2 + (30)2 - 3,925.

Extracting the square root: -

√3,925 = 62.65 =62 2/3 in. (nearly).

Whilst in this particular job it is most convenient to obtain the length of the front from the side, yet there are in practice many cases, as we shall see, where this kind of calculation is most useful. A flange for attaching the hood to the wall must be allowed on the side pattern, and also on the top of front plate; flanges must also be left on the slant line of side for fastening front and side plates together. From the inspection of Fig. 42 it will be seen that the bottom of the hood is wired; hence it will be necessary to make an allowance for wiring on lower edges of sides and front. The amount of this allowance will of course depend on the size of the wire to be inserted, and also on the thickness of the plate used.

Fig. 43.

The following is the general rule: -

Continue to: