Allowance For Wiring

Description

This section is from the book "Practical Sheet And Plate Metal Work", by Evan A. Atkins. Also available from Amazon: Practical Sheet And Plate Metal Work.

Allowance For Wiring

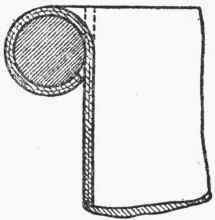

"Add twice the diameter of wire to four times the thickness of metal." A careful study of Fig. 44, and the measurement of the length of centre line of metal will show the above rule to be as near correct as possible. Suppose that 1/4 in. wire be used in the hood, and the sheet iron to be 1-16 in. thick, then the allowance to be added on to net pattern for wire will be -

2 x 1/4 + 4 x 1/16 = 3/4 in.

For the flanges and wire edges to come into their proper positions the corners should be carefully notched, as shown on the pattern for sides. Holes for riveting can be marked and punched in the flange on side pattern, and this used for marking the holes on front plate.

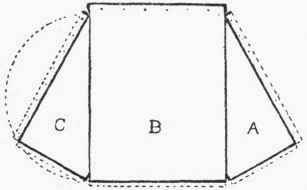

Sometimes angle-iron is used to joint the front and side plates together, and in this case no lap for riveting will, of course, be necessary. Again, sometimes an angle-iron frame is riveted around the bottom, and the two ends let into the wall, and when the hood is constructed in this way no allowance will be needed for wiring. Whilst speaking of wiring it should be remembered that although the above rule for wire allowance on pattern is strictly true for straight wiring, it is not exactly so for the edges of round tapered articles. If the large end of a circular article is to be wired, the calculated allowance will be slightly too much, and in the case of wiring the small end the allowance will be a little too small. In fastening the hood to wall, it is a good plan to bolt a bar of flat iron over the flange at top of hood, as this will materially assist in keeping the hood tight against the wall. A method of marking a small hood in one piece is shown in Fig. 45. If the height and depth are given, one side can be marked out as at A, and the front part B set on this, the remaining side C being described on B by taking the height and depth and marking respectively from the top and bottom of the edge of B. If one only of the dimensions, either height or depth, be obtainable, then the sides can be marked on the front by describing a semicircle, as shown, and marking across with the given dimension from an end of the diameter.

Fig. 44.

The use of the semicircle has an extensive application in sheet and plate metal work, as every pair of lines drawn from a point in the circumference to the ends of the diameter contain a right angle, or are square to each other. This property of the circle can often be taken advantage of in adding sides or ends on to a pattern.

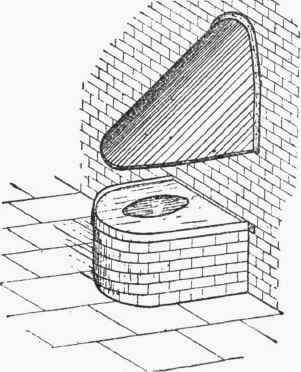

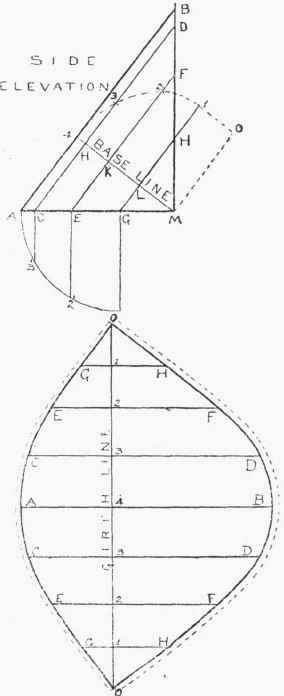

A more expensive hood, both in labour and material, is of the kind required to cover a semi-circular hearth with flat sides, as shown in Fig. 46. The bottom of the hood is, of course, the same shape as the top of the hearth. To set out the plate in the flat required for the hood, the method illustrated in Fig. 47 can be followed. A side elevation of the hood is first drawn, and a quarter-circle described on the bottom equal in radius to half the width of hood. This quarter-circle is divided into three equal parts, and lines drawn up through each point square to the bottom line of hood giving points C, E, and G; and through these points lines are drawn parallel to the line A B. A base line to measure from is now fixed; and this may be drawn in any position square to the front of hood. The most convenient position, however, is when the base line is drawn to pass through a corner of the hood, as in the figure. Now measure the lengths of lines on quarter-circle, and set these distances on corresponding lines above the base line. Thus, H 3 = C 31, K 2 = E 21, and L 1 G l1. The line M O will, of course, be made equal in length to G l1. Join the new-found points with a fair curve, and the length of this will give half the girth of hood. The shape of the curve from 1 to 4, it might be remarked, is a quarter of an ellipse, and this will give the form to which the hood should be shaped on each side of the centre line of front of hood.

Fig. 45.

Fig. 46.

Fig. 47.

In setting out the pattern, first draw a line, and along this mark the lengths 0 to 1, 1 to 2, etc., as obtained from the quarter-ellipse in elevation. Draw lines across, through these points, square to the girth line, and their lengths can be cut off by obtaining the lengths of similar lines in elevation. Thus, G 1 on the pattern equals G L in elevation, and H 1 equals H L. In the same way, E 2 and F 2 will be respectively equal to E K and F K, the other lengths being measured and set off in the same manner. All the points are now joined up with an even flowing curve; best drawn by bending a piece of hoop-iron round through the points, or a strip of wood and marking along.

If a flange is to be thrown off to fit against the wall, this must be allowed for on the pattern, and also if the bottom edge is to be wired allowance must be made for this. Care must be taken to notch the corners properly, so that the flange and wire edge can conveniently be turned over. The wiring around the bottom can be done either before or after shaping the plate, the flange for back being thrown off after the plate is bent.

It should be remembered that the bottom is semicircular in form, with the part from G to M straight, so that in bending it can be shaped to this; or if a very accurate job is required a template can be cut out of sheet iron, or a piece of strong wire bent to the shape of the curve 0 to 4, and this can be used as a gauge in bending. If the hood is large it will be made up in two or more pieces to avoid waste of material. Instead of a flange at back, angle-iron may be attached, and in place of wiring around bottom, cope-iron can be riveted on.

Continue to: