Moulded Lid Or Cover

Description

This section is from the book "Practical Sheet And Plate Metal Work", by Evan A. Atkins. Also available from Amazon: Practical Sheet And Plate Metal Work.

Moulded Lid Or Cover

A lamp-top, or base, lid or cover for a variety of articles, is sometimes made in the shape shown in Fig. 76.

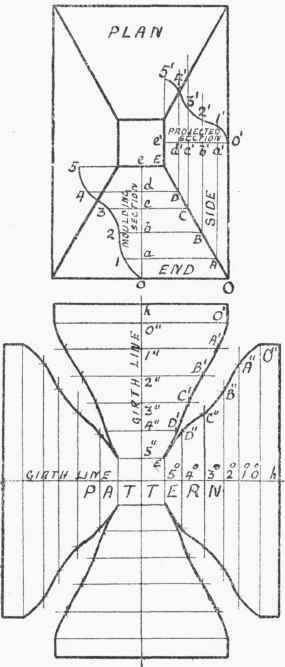

And as this kind of object brings in an important principle, in determining the form of the moulding on two of the cover sides, we will explain the setting out of the moulding section and the pattern for the complete cover. A plan of the cover is given in Fig. 77, on which the moulding section for the ends and the projected section for the sides is also shown.

If the width of the end-moulding (0 e) had been the same as the width of the side-moulding (0' e'), then the same shape of section could have been used for both, and the pattern marked out as explained in a previous chapter. But in all cases where the widths are not the same, the shape of moulding for either end or side (whichever is fixed) must first be set out, and the other projected from it. In this way a proper mitring of the corners can be effected.

Fig. 76.

In Fig. 77 the moulding section on the plan is first marked out as required, this being drawn upon the middle line 0 e, or in any other convenient position. The curve of the section is then divided into five equal parts, the division points being numbered 1, 2, 3, etc. Through these points perpendiculars to 0 e are drawn, and produced to meet the joint line E O. Then, from each of the points of intersection on this line projectors are run along square to, and through, the middle line 0' e'. To obtain the shape of the projected section, the heights are cut off equal to the length of lines on the moulding section. That is, a' 1, b'2', c' 3', etc., are respectively set up equal to a 1, 6 2, c 3, etc. The curve drawn through the points 0', 1', 2', etc. (called the " projected section ,;) will give the shape of moulding for the side that will exactly mitre on to the moulding as set out for the end.

Fig. 77.

The pattern for the cover is laid out by drawing two lines square to each other, and along these stepping the respective girths of the two mouldings. Thus, the lengths 5" to 4", 4" to '6", etc., will be made the same as the lengths 5 to 4, 4 to 3, etc., on the moulding, whilst the distances 5° to 4°, 4° to 3°, etc., will be the same as 5' to 4', 4' to 3', etc., on the projected section. The lengths 0" h and 0° h will, of course, equal the breadth of the rim around the cover.

The small square in the middle of the pattern will be the same size as that in the centre of the plan. The lengths of the construction lines for the pattern will be measured from the middle lines 0 e, 0' e', on the plan, up to the joint line E O. Thus, lines 0" O', 1" A', 2" B', etc., respectively equal 0 O, a A, b B, etc., and lines 0° O", 1° A", 2° B", etc., are equal, respectively, to 0' O, a' A, b' B, etc.

Even curves are drawn passing through each point, and the sheet can then be cut out to the shape as shown.

In making up into the cover shape, care must be taken that the two mouldings are bent to their respective forms, and then there will be no difficulty in jointing. The principle involved in the above example is an important one and worth taking notice of, as it applies to all classes of moulding, beading, etc., where two different sizes have to be jointed together.

Continue to: