Lesson 5. Cousin Ann Tells How Silk Is Made Into Cloth

Description

This section is from the book "Clothing And Health. An Elementary Textbook Of Home Making", by Helen Kinne. Also available from Amazon: Clothing And Health.

Lesson 5. Cousin Ann Tells How Silk Is Made Into Cloth

Last summer Marjorie Allen's Cousin Ann visited her. She lives at Paterson, New Jersey, where there are many silk mills. She told the girls of the Sewing League about the way silk is made into cloth. Shall we too learn how ?

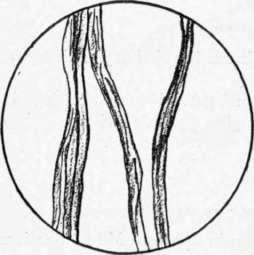

Where is silk manufactured? We know that very little silk is grown in the United States; but we also know that our country leads in the manufacture of silks and uses more raw silk than any other country in the world. France is next and produces very beautiful materials. Most of our silk factories are in the East: in New Jersey, Connecticut, New York, and Pennsylvania. People have tried to raise silkworms here. In 1624 some Frenchmen living in Virginia tried, but were not very successful. Such experiments have usually failed because it costs so much for labor. In 1747 the governor of Connecticut wore a coat and stockings made of silk produced on his place. We use about 85 per cent of the silk manufactured here. What per cent is, then, exported? In 1876, at the great Centennial Exhibition in Philadelphia, Marjorie's grandmother saw wonderful exhibits of silk woven in many colors, and even beautiful woven pictures of silk. Has any one ever seen a woven picture of silk? Have you ever seen one tiny fiber of silk as it looks under the microscope? What do you notice?

This is what Marjorie's cousin from Paterson told the girls. They went to one room at the mill where there were great bales of silk, weighing about 100 or 150 pounds, but not quite so heavy or large as a bale of cotton. When opened there were many hanks in each bale; tied up, five or ten in a bundle. These hanks were taken first to a man called a throwster. Silk throwing means soaking the skeins to remove more of the gum, and winding the silk from the skein to a spool. This is done by soaking in warm water, drying, and then placing the silk on swifts, or reels. Have you ever seen a reel for winding? (See Fig. 78.) It holds the skein of silk. The ends are taken, and the machine unwinds from the skein and winds the silk on spools. In one skein there are from 75,000 to 200,000 yards of silk. The spools are then placed in a machine which cleans and twists two of these spool threads together to form one, and then winds it off on new spools. This twisted silk is called "organzine." Isn't that a queer name?

Fig. 77. - Silk fibers magnified.

It means the thread used in a loom for the warp or strong threads. Why are twisted threads stronger?

Try, and see if they are.

Silk is a most perfect fiber; and does not have to be prepared as much as cotton or wool. Sometimes it is twisted a very little for the warp. The filling thread has a queer name, too. It is called the "tram," and need not be of so good a quality of silk as the strong warp, nor so tightly twisted. Cotton spinning is different from silk throwing; but both mean getting the fibers ready for weaving.

There are many beautiful colored silks. Silk is usually dyed (Fig. 79) in the yarn in hanks. The poor qualities, however, are dyed after the silk is woven into the piece. Silk is dyed by dipping the skeins or yards of silk in great vats of dye. For dyeing, the coal-tar products (aniline dyes) are used. Did you know that coal could produce such beautiful colors? That is a long story of the many wonderful things which can be made from tar. Do you know that 25 per cent of the weight of the raw silk is made up of the gummy substance? The dyer boils out some of the gum; and, if he wishes to produce cheap silks and make much money, he makes up for the weight of gum boiled out, by-using tin. The silk is dipped in bichloride of tin or other substances; and it takes up, or absorbs, until sometimes it weighs twice or even four times as much as the boiled-off silks. This tin is bought for silk. Women who do not know think they are buying heavy silk and are getting a good quality because it is so heavy. This solution of tin rots the silk, and, when the silk comes in contact with light and air, it crumbles away. Perhaps you have at home a sample of silk which has done this. Marjorie's Cousin Ann saw some petticoats of silk which went to pieces just hanging in a closet. Sometimes that happens when store keepers keep the petticoats for some time. One can see the holes by holding the silk up to the light. In order to know what one is buying one must study about materials and about how they are made.

Courtesy of Cheney Bros.

Fig. 78. - Silk winding.

Courtesy of Cheney Bros.

Fig. 79. - Silk dyeing.

Have you ever seen a picture of silk being dyed in the skein? Marjorie's cousin says it is done by machinery. See how many skeins are on the big wheel, or drum as it is called. As it turns, the skeins are dipped in the vat of dye.

Courtesy of Cheney Bros.

Fig. 80. - Warping or preparing silk for the loom.

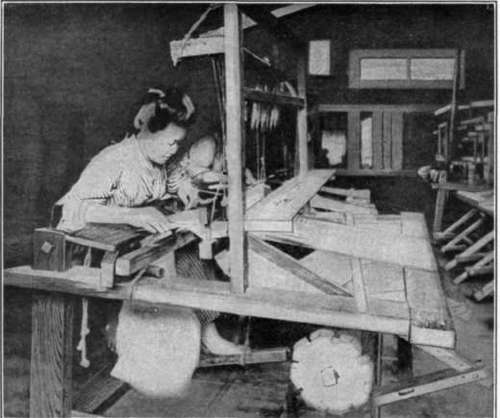

After the warp threads are twisted and wound on spools, the workman places the spools in racks (see Fig. 80). They are then unwound again on to a very large roller, as you can see in the picture. The large roller is then put into the back of the loom, and the warp threads are drawn through and prepared so they are attached to the roller where the cloth is to be rolled after it is woven. Do you remember how we found the cloth and the warp rollers when we were studying about how cotton cloth is made? For plain silks a loom is used very much like the looms for weaving cotton cloth (see page 69); but, for fancy silks and beautiful patterns and designs, the Jacquard loom like the picture (see page 124) is necessary. This wonderful machine was invented by a Frenchman, Joseph Marie Jacquard, in 1801. The cards are cut in tiny holes which regulate the pattern and make beautiful designs. The cards control the warp threads and regulate which threads are to be up and which down, as the shuttle passes over and under. The shuttle is lined with soft seal skin to protect the silk fibers of the filling thread on the bobbin as they unroll.

Courtesy of Cheney Bros. Fig. 81. - Silk weaving on a hand loom in Japan.

Would you too not like to visit a silk factory?

Perhaps come day you may be able to go to Paterson or to some large city, and may see all the wonderful things which Marjorie's cousin saw. The book pictures will give you a good idea of how a mill or factory looks inside. It is a very busy place. Perhaps your teacher may be able to get some stereopticon or motion picture views to show you, as Miss James showed the Pleasant Valley children. She used the church lantern. Some of the mothers and fathers came, too, to hear the story about silk.

Exercises And Problems

1. Find on your map the most important city in the United States for the manufacture of silk.

2. Write a story about the silk "throwing."

3. If there is a silk mill in your neighborhood, plan to visit it with your teacher.

4. Look up the story of Jacquard, the inventor of the loom devices for making beautiful patterns.

Continue to: