How To Use Glue

Description

This section is from the book "Things To Make In Your Home Workshop", by Arthur Wakeling. Also available from Amazon: Things to Make in Your Home Workshop.

How To Use Glue

In building and repairing, glues play such an important part that we should know more about these sticky substances and how to use them so that the articles made or mended with their aid will hold together under all reasonable conditions of everyday use and even abuse.

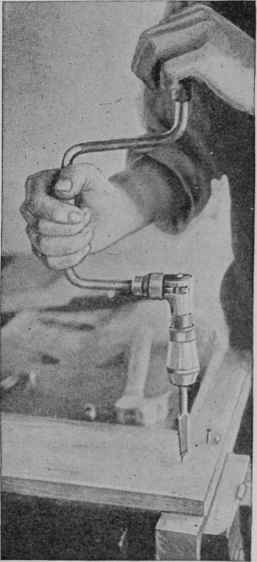

Fig. 17. - Using a brace and bit make; easy work of driving a screw.

Glue has been used for many centuries. Hack in the days of the Egyptian pharaohs it was used to build beautiful veneered work. Through the centuries its have been multiplied.

Like the earliest glues, the bulk of those made today are from scraps of the hides, the fleshings, and the bones of animals. They are sold in ground, flake, and sheet forms.

Liquid glue usually is made from fish stock, which is washed and cooked in a similar way to animal stock. A very interesting characteristic of glue made from fish stock is that the gelatine or extracted glue does not jell, but remains in a fluid state at ordinary temperatures.

Fig. 18. - Weighing both the dry glue and water is necessary to obtain the best results.

Cheap liquid glue should be avoided, because it gathers moisture. It contains large amounts of salts, such as sodium chloride or common table salt. These salts absorb moisture just as salt on the table will do and on a wet or humid day the glued materials are apt to fall apart.

Good liquid glue has many advantages over other adhesives for use in the home workshop. It is purchased ready for use, so no weighing, soaking, or heating is required. On account of its slow setting quality, the workman is given ample time to get the joints properly together, whereas with hot glue the work must be done quickly before the glue sets or jells. Slow setting also means good penetration of the glue into the wood and added strength. When strength is compared, good liquid glue is as strong as good animal glue.

During the war, glues made from casein were developed rapidly. Casein glues conic in dry powder form and are prepared simply by stirring into cold water. They make a strong, moisture-resisting joint. For glued work exposed to outside weather conditions they have no superior. They are used universally in building airplanes.

There are other so-called glues made from starches, dextrines, and blood albumen, which are used commercially for many purposes.

To obtain the best results with glue in the home workshop, we must have certain equipment. This should include a can of the best quality liquid glue, some high grade cabinet flake glue, a jacketed gluepot, two glue brushes, a cheap dairy thermometer, clamps, and hand screws.

Gluepots can be purchased at any hardware store. The outer vessel is filled with water and heated over a gas-burner or stove. There are more expensive pots heated by electricity.

Good bristle glue brushes with brass ferrules cost from 60 cents to S1 each, according to size. However, a basswood stick soaked in water for from two to three days and hammered so that the end fibers become separated makes a good substitute. As the end wears away, more of the fibers can be separated. If a brush gets hard, soaking it in water will restore it to its soft condition. The dairy type of thermometer costs about $1. Car-riagemakers' iron clamps and carpenters' hand screws cost from 40 cents up.

The various utensils used with glue should be cleansed carefully and frequently with boiling water. Any small amounts of spoiled glue remaining in the gluepot or on the brushes greatly weaken and sometimes ruin fresh glue.

When liquid glues are set aside after use, the containers ought to be closed tightly. If through evaporation the glue becomes too thick, dilute it slightly with clean, warm water. Do not use vinegar.

Ground, flake and sheet glues should be kept in a clean, dry place, preferably in a tightly covered container of some sort.

In preparing dry animal glues, the glue should be soaked until soft in clean, cold water. It always should be stirred into the water to insure complete soaking. Sheet glues should be allowed to soak at least 12 hours; flake glues, from 4 to 9 hours, according to thickness of the flakes; and ground glues from 2 to 4 hours. It is advisable to let them all soak overnight or prepare them in the morning if they are to be used during the evening.

The amount of water depends upon the grade of glue. The water-taking quality of hide glues varies from l½ to 3 parts of water to 1 part of glue. Medium grade hide glues take 2½ parts of water to 1 part glue by weight. While bone glues are not recommended for wood jointing, sometimes they are used and they take only from 1 to 1½ parts of water.

Fig. 19. - A dairy thermometer may be used to avoid accidentally heating animal glue beyond 150° F.

Both hide and bone glues have a wide range of grades, but it pays to use the best glue obtainable.

It always is best to weigh the glue and water each time after the right proportion has been determined (Fig. 18). Glue cannot be prepared by guesswork. Animal glue should not be too thick. It is necessary for glue to penetrate into the articles to be glued in order to bind them together. If too thick, it jells on the surface.

Scales were not mentioned in the list of equipment as they are expensive. Usually a local store will allow you to weigh your glue.

After soaking, the glue should be dissolved in the gluepot. If the soaking is complete, the glue will melt readily. If all the water has not been absorbed, leave it with the glue in the pot. Be sure there is water in the jacket of the pot.

Continue to: