Sandpapering A Surface

Description

This section is from the book "Shop Projects Based On Community Problems", by Myron G. Burton. Also available from Amazon: Shop Projects Based on Community Problems.

Sandpapering A Surface

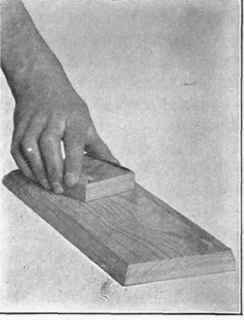

Paragraph 17. In sandpapering a surface, the purpose is to make it absolutely smooth. Sandpapering should not be begun until the surface has been made as smooth as possible with a plane or a scraper. Sandpaper must not be used to remove the roughness left from the saw nor any other imperfection in the work. This must be removed by a cutting tool. A piece of fine sandpaper should be wrapped around a block, as shown in Figure 34, then the block should be grasped firmly with the thumb and fingers, holding the sandpaper in position, while the block is pushed back and forth in the direction of the grain. (See Figure 34.) The sandpapering block should never be pushed across the grain. If sandpaper is used crosswise of the grain it will leave ugly marks which can scarcely be removed. So, as a rule, you should adopt the motto of "never sandpaper across the grain." Beginning students are inclined to rely upon sandpaper too much. Fine workmen use sandpaper only for the final finish on the piece of material. They make the cutting tools do most of the work which a beginner attempts to do with sandpaper.

Sandpaper is made in a great many grades or degrees of fineness, ranging from 00, which will probably be the finest you will require, to No. 3. No. 1 will probably be about the roughest you will need. Most of your work will be done with No. 0. Many students waste sandpaper by throwing it away when it is still valuable. You should not take a new piece of sandpaper until the old one is entirely worn out. In fact, a piece of sandpaper does better work after it has made several strokes across the board, because its first roughness is then worn down and it is smooth enough to leave a fine finish on the board. Worn sandpaper should be saved in the shop, for it is useful in polishing tools, where sharp sandpaper would be too rough and would scratch them.

Note: Somewhere in the shop there should be a box into which the partly worn sandpaper should be thrown; it would not only be handy for use, but would save expense.

Figure 34.

Continue to: