19. Squaring-up Mill-Planed Stock

Description

This section is from the book "Woodwork For Beginners", by Ira Samuel Griffith. Also available from Amazon: Woodwork For Beginners.

19. Squaring-up Mill-Planed Stock

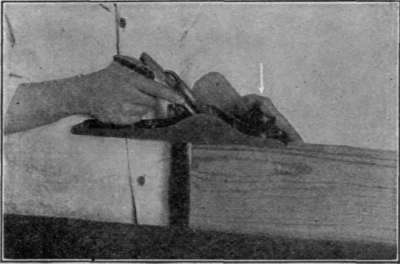

Fig. 46. Position in Edge Planing.

First Method:

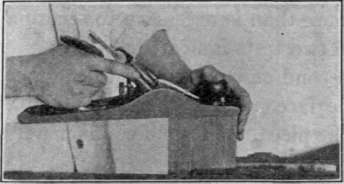

Fig. 47. Starting the Stroke.

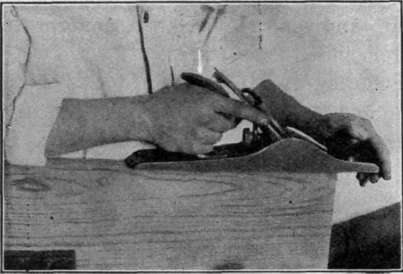

(1) Select and mark one of the broad surfaces for a face side, Fig. 43. (2) Select and plane a face edge (a) square to the face side and (b) straight as to length. Place the piece in the vise and assume a position as in Fig. 46. Plane the edge straight as to its length and square to the face side just prepared. In elementary manual training the jack-plane will be used for this purpose. Press firmly upon the knob in starting the stroke, Fig. 47, and upon the handle at its close, Fig. 48; otherwise the ends will be lowered more than the middle of the board. In planing a long board it will be necessary to stop and start some of the strokes in the middle of the length of the board. It is possible to do this without leaving any plane marks by lowering the plane gradually in starting and raising it gradually in stopping a stroke, getting what is known as a "feathered" shaving. Take off no more shavings than are necessary to secure the required straightness and squareness.

Fig. 48. Finishing the Stroke.

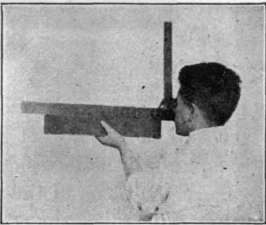

Fig. 49. Sighting for Straightness.

Fig. 50. Straight-edge Test.

After the first stroke or two, hold the piece toward the light, as in Fig. 49, close one eye and sight for straightness. The beginner will do well to make use of a straight-edge test, as in Fig. 50, until he has made sure he can "sight" correctly. No light should appear between the edge of the stock and the straight-edge when they are held between the eye and the light.

The second test, that for squareness of the edge, is made by holding the try-square as in Fig. 16 and sighting toward the light. Hold the beam firmly against the face side and test at a sufficient number of places along the edge to determine what the true condition is.

In edge planing the beginner should remember that his plane-iron is slightly rounding on its cutting edge, and that all he needs do to take a shaving at any given place is to continue holding the plane level but move the whole plane body over until the rounded central part of the cutter is immediately over the "high" place on the stock. Fig. 51 shows the plane placed to take a shaving off the edge at the arris nearest the worker. The final stroke should be taken the full length of the stock and down the middle of the edge that any slight unevenness resulting from partial strokes may be removed.

Place the face mark on this edge when it meets the required tests, marking it as in Fig. 43.

(3) Plane the second edge (a) square to the face side, (b) straight as to its length and (c) parallel to the face edge.

Fig. 51. Removing a High Arris.

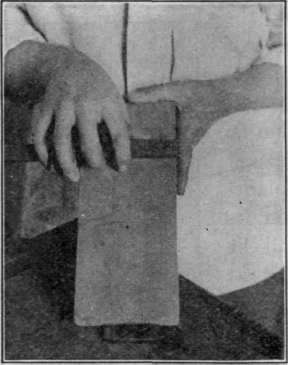

Where a definite and exact width of board is required, a line is gaged from the face edge by means of a marking gage set as in Fig. 23 and held as in Fig. 52 with the head against the face edge. The line should be lightly made and the planing continued until half of the light V-shaped groove is removed. Test the edge for squareness frequently as the gage line is approached that the edge may be square when the line is reached. If the gage line is approached properly the edge should be straight and parallel to the face edge. It is well for the beginner to test this edge for straightness, and for width with the sliding try-square test.

Where the waste stock is more than 3/16 in. it should be ripped parallel to the gage line and about 1/8 in. away from it.

If much stock is to be removed the plane-iron may be set so as to take heavy shavings. When nearing the gage line it should be set to take fine shavings.

Not infrequently, while no definite width is required, it is desired to have the second edge planed straight, square to the face side, and parallel to the face edge. In such a case, the worker simply planes the second edge until it is straight, square, and meets the sliding try-square test illustrated in Fig. 19.

Fig. 52. Gaging.

(4) Square up one of the ends (a) to the face side,

(b) to the face edge. Ends may be finished in two ways: by sawing accurately to the line squared across from the face edge, Figs. 15 and 32; second, the end may be planed square. Ends sawed to make joints are usually "undercut" very slightly; that is, the sawing is done in such a way as to leave the face slightly longer than the back, thus insuring a fit on the face.

In planing an end, the plane-iron should be very sharp and set very shallow and true.

Test the end by holding the blade of the try-square across it with the beam against the face side and then the face edge, Figs.

17 and 18. End planing differs from edge and surface planing in that the plane-iron must not be allowed to cut entirely across the piece or the far edge will be broken off, Fig. 53. To avoid this, plane about two-thirds of the way across the end and then reverse the piece and plane from the other edge, Fig. 54. Test frequently as indicated above, and plane no more than is necessary to secure a result which meets the two tests indicated.

Fig. 53. End Planing; First Position.

Fig. 54. End Planing; Second Position.

(5) Square up the second end (a) square to the face side, (b) square to the face edge. Where no definite length is required for the piece, the second end is merely planed as was the first end, the same tests being applied. That is, the try-square is held with its blade across the end and its beam against the face side and then against the face edge, Figs. 17 and 18.

Fig. 55. Measuring Length.

If the end is to be sawed square without planing, the try-square and pencil, or knife for accurate work, will be used to scribe a line across the face side and one edge, as in Fig. 15. The stock is then sawed as in Fig. 32.

Where a definite length of stock is prescribed, the rule should be placed as in Fig. 55, and the exact length marked. A line is scribed through this mark, Fig. 15, and the surplus stock either sawed exactly to the line where a sawed joint is to be made, or sawed about a scant 1/16 in. outside of the line where a perfectly smooth end is to be left. After this latter sawing, the 1/16 in. surplus stock is removed with the plane.

Continue to: