September 1909. Vol. 1. No. 7. Why It Pays

Description

This section is from the "Studio Light And The Aristo Eagle - A Magazine Of Information For The Profession 1909" book, by Aristo Motto. Also see Amazon: Studio Light And The Aristo Eagle - A Magazine Of Information For The Profession 1909.

September 1909. Vol. 1. No. 7. Why It Pays

It pay's to buy the goods that are consistently and persistently advertised. There is no greater fallacy than that contained in the statement that non-advertised goods can be sold cheaper because the expense of advertising is not added to their cost. The sole reason for advertising is to create a market and an ever growing demand for the product or products advertised.

It requires no lengthy explanation to demonstrate that any product produced in large quantities can be manufactured and sold cheaper than those made in small lots. The manufacturer in large quantities can not only decrease the cost, but at the same time can improve the quality. The purchase of raw materials in quantities can command the market; those that have these materials to sell are anxious for his trade - they quote him the lowest figures - they supply him with the choicest grades - and further, when a shortage in supply occurs, the large purchaser will be the one favored invariably.

The manufacturer in small quantities must put up with inferior facilities for manufacture he must, in view of his small output, perform many of the operations of manufacture by hand, while the large producer can stand the expense of the construction of special machinery that will perform these same operations a hundred fold cheaper and better.

The small manufacturer in many instances is at the mercy of the seller of raw materials as to quality - the large producer can and does have in his service, experts to make accurate scientific tests for quality, and by so doing can establish a standard of quality impossible for the smaller concern.

The non-advertiser or semi-occasional advertiser has a smaller field for his wares and can, and in fact has to take some chances as to quality. The heavy advertiser, with his big output and growing field, does not dare to take any chances as to quality. He must make his products live up to their advertised quality - in fact, if he is wise he will, and usually does, make them even better than advertised in order to please the ultra fastidious.

It pays to buy the well advertised products because the quality has to be there, or else the advertising outlay would become an expense instead of an investment.

In some instances the price of the advertised goods may be higher than that of the other kind - but the quality is also higher and that's what counts.

Angelo Sepia From Toronto

Increased sales and growing popularity with the best photographers have brought about a change in the Angelo Sepia business, which will be of benefit to the profession in Canada. From September 1st this paper has been supplied from Toronto according to the list given on page 29, but only in the sizes shown, the demand for other sizes not being large enough to warrant packing them.

There Is Good Money In Good Enlargements.

Read Carefully The Article On Page Twenty.

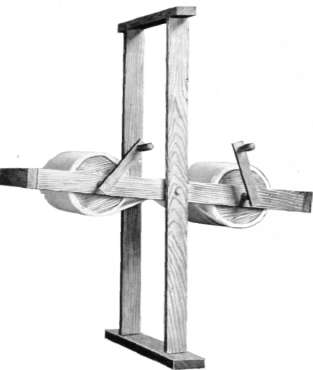

A Simple Print Drying Machine

Practically every photographer has some pet method for concave print drying, but the machine constructed by Mr. L. Frank Griffith, of Salt Lake City, works so well and is so easy to construct that we afford a description of it for the benefit of the profession in general.

As shown in the illustration the machine consists of two slatted, wooden ended cylinders or rolls, fixed in a swinging frame, supported by uprights; the uprights being braced, top and bottom, by cross pieces. From one cylinder is attached the end of a roll of cheese cloth, and of blotting paper, the loose ends of the cheese cloth and blotting paper are then brought over the axis rod supporting the swinging frame, to give a slight tension, and then rolled upon the other cylinder for a few turns.

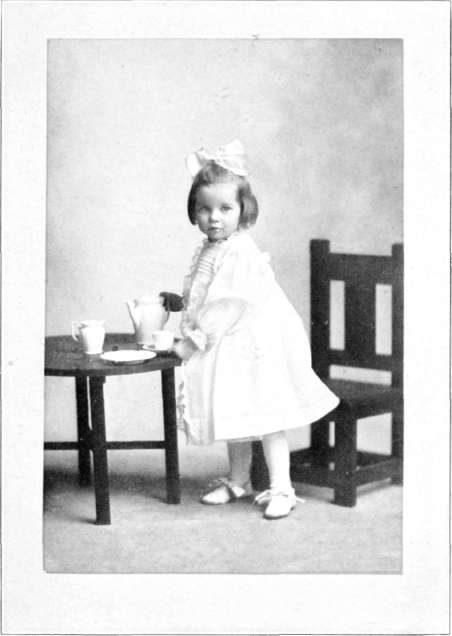

From An Aristo Platino Print By C. F. Bretzman Indianapolis, Ind.

To use, the prints are first surface dried by pressing lightly between dry blotters, then removed and placed between the blotting paper and the cheese cloth with the face of the print against the cheese cloth. The cylinder is then revolved by means of the handle shown in the cut, until all the prints to be dried have been rolled in.

Under average conditions, where a current of air can strike the machine, the prints should dry perfectly over night.

Continue to: