Alcohol. Part 9

Description

This section is from the book "The Engineer's And Mechanic's Encyclopaedia", by Luke Hebert. Also available from Amazon: Engineer's And Mechanic's Encyclopaedia.

Alcohol. Part 9

From the circumstance of alcohol boiling at a temperature considerably below the boiling point of water, many persons have supposed that its vapour might be advantageously substituted for steam as a prime mover of machinery. The first suggestion to this effect we think originated with the Rev. E. Cart wright; but we are not aware of any attempts to carry it into effect previous to those of Mr. Howard, who took out a patent in 1825, for an apparatus for the purpose, and endeavoured with great perseverance to bring it to perfection, but, we believe, without success, as we cannot find that any engines of this description have been brought into use. The following description, with the annexed engravings, will explain the nature of the apparatus. A and B are two cylinders of equal capacity, communicating at the lower part by a pipe, or passage C. These cylinders contain a quantity of oil, mercury, or other fluid, (which will not rise in vapour at the temperature to which it is to be exposed,) sufficient to fill the base of one cylinder, and nearly the whole of the other cylinder.

Within the cylinder B is a piston exposed above to the pressure of the atmosphere; it has a piston rod, and is packed in the casual manner.

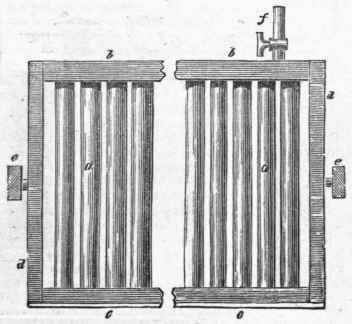

In the other cylinder A is a thin metallic dish D floating freely upon the surface of the oil, or other fluid, before-mentioned. This latter cylinder has a top, per fectly air-tight, fastened down upon it, and through a stuffing-box in the centre of the top, passes a tube E terminating within the cylinder in a small nozzle, pierced with numerous small holes. In the cover of the cylinder is a flap-valve G, which is opened by a rod II striking it; the valve is kept up to its seat by a crane neck-spring above it; the valve-rod works through an airlight stuffing-box I; a safety-valve K is placed on the top of the cylinder. In the piston is an orifice fitted with a plug, by means of which the height of the fluid above the piston (it should always be kept a little above the piston) may be regulated; and at N is a cock, by which the fluid may be withdrawn from the cylinders. The cylinders, and the fluid contained therein, are heated by a sufficient number of argand lamps placed beneath them; and the cylinder A, and the lower part of the cylinder B, are surrounded by a casing, leaving a small space between them, so as to confine and carry the heated air entirely around them.

On the top of the casing is a chimney P provided with a register Q, the better to regulate the heat of the air within the casing. By mean3 of a small force-pump R, which is worked by the engine, a small quantity of alcohol is drawn from the condenser, and thrown suddenly through the pipe E on to the floating-dish D, which, being previously heated by the oil, or other fluid medium, on which it floats quickly, converts the alcohol into vapour, which, pressing upon the dish, and the oil on which it floats, forces the oil through the horizontal passage, and raises the piston to its highest point of elevation. The valve in the cylinder A being now opened, the vapour escapes by a tube S into a separate vessel, and is there condensed; the piston then descends by the pressure of the atmosphere, and the dish D is carried again to the top of the vapour cylinder A. The tube S is divided in the middle by a flat ring a of wood, cork, or other non-conducting substance, making an airtight joint, and is inserted into a circular tube, or hollow ring V V, from which a number of small thin copper pipes U U descend. The lower ends of these pipes are inserted into another vessel W, which forms a reservoir for the vapour when condensed.

The liquid formed by the condensation of the vapour, may be drawn off by the pipe and cock d. The outer and upper part of the condenser, has upon it a circular open basin X, which is kept supplied with water by a pump, or any convenient means. The small tubes U are each wrapt round with flannel, or other porous substance of like nature, the upper end of which hangs over the bason X into the water ; and, acting like a syphon, conducts the water over the surface of the tubes U, down into a vessel Y below them. Within the circle, formed by the small tubes, is a fanner kept in rapid motion by the engine, by which means a stream of air is thrown upon the wet flannel, and the heat is, consequently, more rapidly extracted from the condenser. Previously to setting the engine to work, it is necessary to withdraw the air from the vapour cylinder and condenser, which is done by means of an exhausting pump or syringe, applied at c, to a pipe with a stop-cock b fitted on the top of the condenser. The liquid to be converted into vapour for working the engine, is introduced into the reservoir at the bottom of the condenser, through a tube e closed by a screw cap f. Fig. 2, shows a method of affecting the condensation by injection.

The pipe * conveys the vapour from the vapour cylinder into the condenser g, which is formed of copper as thin as the pressure will admit of, and which contains a portion of alcohol, which may be introduced by the tube e as before, or by a funnel o and a stop-cock p on the top of g. A lifting pump h is put in motion by the engine, at the same time that the valve G (in Fig. 1) is opened, and the pump withdrawing a quantity of the alcohol from the lower part of the condenser g, injects it into the same vessel at the top, after passing it through a pipe or worm i, the end of which k being pierced with many small holes, the liquid is dispersed throughout the vessel q, and condensing the vapour therein, falls with it to the bottom. Part of this liquid is again thrown into the vapour cylinder by the pump R, to be converted into vapour, as before described; and part of it is again employed to condense the vapour, as last mentioned. The condenser g and the tubes connected therewith, are placed in a cistern which is kept constantly full of cold water. The engine above described acts against the pressure of the atmosphere, which also effects the return stroke of the piston.

Continue to: