How Materials Differ Because Of Finish

Description

This section is from the book "A Girl's Problems In Home Economics", by Mabel B. Trilling. Also available from Amazon: A Girl's Problems in Home Economics.

How Materials Differ Because Of Finish

When you examine your cotton samples you can see that even if they should all be of the same color and made with the same weave, they still may differ in appearance. Some of them may be fuzzy in texture, others may be silky, others may be stiff and some may be soft. These different effects may be produced by the different ways in which cloth is finished. In the following paragraphs you will learn something about the different ways in which cotton cloth is finished.

Sizing Cotton Cloth. - This is a process of adding stiffening to the cloth just the same as starching clothing after it has been washed. A little sizing helps the general appearance of the material. Some materials such as percale and organdy are purposely stiffened with sizing so as to have a crisp effect. Other materials such as nainsook are finished so as to have a soft effect. When a great deal of sizing is used to fill up the spaces in a loosely woven material in order to give weight and firmness to the fabric, it is not a good finish. You should be able to detect this because as soon as the material is laundered the sizing washes out, leaving a thin, sleazy material.

Something to Do. - Test some of your cotton samples for sizing by rubbing and scraping with a finger-nail. Wash one-half of each sample and after it is dry compare with the unwashed part to see if any sizing washed out.

Calendering Cotton Cloth. - Calendering the cotton cloth is like ironing starched cotton garments after they have been washed. It is for the purpose of making the cloth smooth and glossy and is done by passing the cloth between heavy, hot rollers. Cotton garments such as collars and cuffs that are heavily starched and ironed with a hot iron are very smooth and glossy. So it is with cotton cloth that has been heavily sized and passed through very hot and heavy rollers. Have you any samples that show the effect of being calendered? If your samples have been laundered they may not show this effect of calendering because it disappears when cloth is laundered.

Mercerizing Cotton. - Do some of your cotton samples look silky and lustrous? This effect is produced by putting the yarn or fabric through a bath of strong caustic alkali while the yarn or cloth is kept tightly stretched. This changes the appearance of the cotton from a dull effect to a lustrous, silky appearance. At the same time it increases the strength of the cotton and makes it absorb dye more easily. This extra process of mercerization makes a fabric cost about three times as much as an ordinary cotton material. It also improves the appearance and wearing quality of the material in every way. Materials that are well mercerized do not lose their silky effect when laundered. Poplins, ginghams, English broadcloth and chambrays are often mercerized.

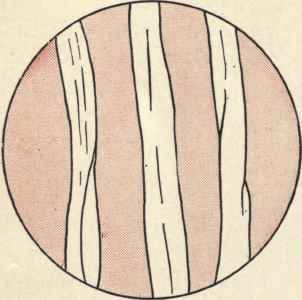

Something to Do. - Sort out the samples of mercerized cotton which you have. Untwist a mercerized cotton yarn and examine a fiber under the microscope. The picture in Fig. 88 shows how the fiber will look. How does it differ from the cotton fiber before it is mercerized?

Singeing Cotton Cloth. - Cotton cloth generally has a tiny fuzz on the surface caused by the ends of the fiber. Sometimes this fuzz is singed off by passing the cloth quickly over gas flames. This makes a smooth surface. Cotton-lisle thread is generally made by using long-fibered cotton tightly spun and finished with calendering and singeing. Cotton-lisle stockings and cotton-lisle underwear are made in this way. Underwear made from lisle thread is especially light-weight and cool. Try to find two samples of cotton material, one that shows the tiny fuzz and another that has been singed.

Crepe Effects. - -Everyone knows that crepe materials are made with a crinkly surface. Among your samples you will probably find cotton crepe underwear material and crepe kimono material. You may also have seen the kind of bedspread made with a crepe effect that is called riplette. There are different ways of producing crepe effects in materials. Sometimes the crepe effect is produced in the weaving by holding certain sets of warp yarns tight and others loose while the weaving is being done. Another way of producing a crepe effect is by printing stripes of caustic soda on a material. The parts which are printed shrink, causing the other parts to crinkle up, thus producing the crepe effect. Still another crepe effect is produced by weaving the cloth out of yarns with different twists.

Fig. 88.

Napping. - Have you wondered how the soft, fuzzy surface is made on such materials as cotton flannel and flannelette? It is done by scratching the surface of the cloth with tiny hooks, so that the ends of the fibers are raised from the cloth. The cloth is passed between rollers which are covered with these tiny teeth or hooks. Sometimes napping is called teazeling, because, instead of using wire hooks, a kind of prickly burr called a teazel is used to scratch the surface of the cloth. Do you know if the teazel grows near where you live? After the fibers have been raised they are sheared off to make them even and then the material is steamed and pressed. The shearing machine cuts the nap as a lawn-mower cuts the grass.

For Your Notebook. - Find samples which illustrate each of these six finishing processes and mount them in your notebook.

A Topic for a Special Report. - There are many other things to learn about how cotton cloth is finished. Any girl who has time can make an interesting report to the class on this topic. There is a list of references at the end of this chapter which will be helpful.

How Wool Materials Are Affected by Finishes. - Some of the same finishes that are used for cotton are also used in finishing woolen materials. It is easy to pick out the wool materials, such as heavy coatings, blankets and sweaters that are finished by napping. Perhaps you will find a wool sample of material that is finished with a crepe effect.

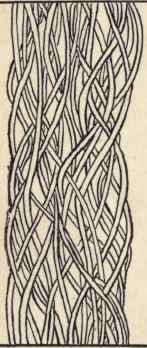

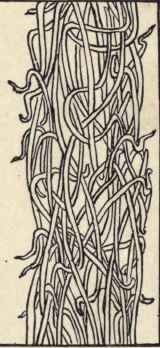

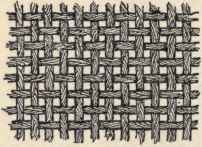

When we speak of the finishes on materials made from wool it is necessary to distinguish between worsteds and woolens. Worsted yarns are made by combing long wool fibers so that they lay parallel, as shown in Picture 1 of Fig. 89. In woolen yarns the fibers are criss-crossed back and forth, as in Picture 2. The difference in texture and appearance of fabrics made from these two yarns is at once apparent. The long, smooth fibers in the worsted yarn give a smooth, lustrous surface, such as is found in serge, gabardine and tricotine. These materials naturally require very little finishing after they have been woven. The surface of a material made from a woolen yarn is rough and requires more finishing after weaving. Felting or Fulling. - This is a method used in finishing wool cloth. After weaving, the cloth is put into hot, soapy water and then run between heavy rollers. This causes the material to shrink, just as wool stockings shrink when improperly laundered. This makes the material closer and firmer, sometimes shrinking it to one-half its original width and length. Do you remember what causes the wool fiber to shrink? If you have forgotten, you can find the answer to this question on page 137. The difference in wool cloth before and after felting is shown in Fig. 90.

Fig. 89.

Fig. 90.

Do you know how your felt hat is made? You can see by examining it that it was not made by a weaving process. The fibers are firmly matted together. How do you think it is possible to make a piece of material without weaving the threads together? Why is it possible for hair or wool fibers to become so interlocked as to form a fabric without weaving?

For Your Notebook. - Mount samples of wool materials in your notebook to show (1) worsted material, (2) woolen material, (3) napped material. Add paragraphs describing other finishing processes used for wool materials.

How Linen Is Finished. - Linen is a material that requires comparatively little finishing. However, its luster and beauty are increased by beetling. This process consists of pounding the cloth until the fibers are flattened. This effect on the linen does not disappear after laundering.

The natural color of linen is gray or brown, and since we use so many white towels, tablecloths and napkins, the bleaching of linen is a particularly important finishing process. The cheaper grades of linen are sized and calendered as cotton materials are. Too much sizing can be detected in the same way as in cotton.

How Silk Materials Are Finished. - You will find by examining your samples that some of the same finishes are used with silk that are given other materials. For example, crepe de chine is finished with a crepe effect. Silk materials are passed over gas flames to burn off the ends of the fibers and are sized with starch or glue to stiffen them. Cheap grades of silk are heavily sized to make them appear of better quality than they are.

Another way of making silks seem heavier and firmer is by means of weighting. This consists of dipping the silk into a solution containing salts of tin and other substances. These metals or substances have, of course, been dissolved in a fluid. When the silk is taken out it is much heavier than when it was put in. Sometimes it is three or four times as heavy. This weighting is usually done when the silk is being dyed. It is considered legitimate to weight silk a certain amount, and if properly done it does not impair the fabric for ordinary wear. If the silk has been too heavily weighted, however, the silk will not wear well. Slits and broken places soon appear in the cloth. This will happen even if the garment is hanging in the closet.

Your Notebook. - Plan two pages in your notebook for silk and linen finishes. You might mount samples of bleached and unbleached linen and silk crepe. Add paragraphs describing other finishing processes used for silk and linen.

Standard Materials. - There are certain standard textile materials that we should be able to identify. These materials are commonly used for clothing and household furnishings. We call these standard materials because it is always possible to buy the same materials under the same names. Many other materials are made slightly different and given new names with each season. It is more important for us to first learn to recognize the standard materials. You should be able to recognize at least twenty cotton materials used in clothing and household furnishings, ten woolen materials, ten silk materials and ten linen materials. Have a class discussion and decide what standard materials you should know.

How Many Materials Can You Recognize? - Arrange a class contest in the recognition of materials. Make your own plans and rules for this contest.

Continue to: