Ironing Tips

Description

This section is from the book "The Boy Mechanic Vol. 1", by Popular Mechanics Co.. Also available from Amazon: 700 Things for Boys to Do.

Ironing Tips

Iron Rest For An Ironing Board

A flatiron rest can be made on an ironing-board by driving a number of large tacks into one end of the board. The tacks should be about 1 in. apart and driven in only part way, leaving about 1/4 in. remaining above the surface of the board. The hot iron will not burn the wood and it cannot slip off the tacks. This iron rest is always with the board and ready when wanted. --Contributed by Beatrice Oliver, New York, N. Y.

![Instantaneous Crystallization [288]](images/Instantaneous-Crystallization-288.png)

Sad Iron Polisher

A small amount of wax is necessary on an iron for successful work. The wax is usually applied by hand to the heated surface of the iron. A much better and handier way is to bore five or six holes in one end of the ironing board to a depth of half its thickness, filling with wax, beeswax or paraffin, and covering them over with two thicknesses of muslin.

The rubbing of the hot iron over this cloth absorbs just enough of the wax to make the iron work smoothly. When the supply of wax is exhausted, it can be easily renewed. --Contributed by A. A. Houghton, Northville, Mich.

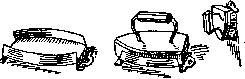

A Flat Iron Rest

The iron rest and wall hanger shown in the sketch is made of sheet iron. The upturned edges of the metal are bent to fit the sloping sides of the iron. The holder and iron can be moved at the same time. --Contributed by W. A. Jaquythe, Richmond, Cal.

Illustration: Board or Wall Iron Rest

Continue to:

More:

- How To Hang Your Hat On A Lead Pencil

- Reversing-Switch For Electrical Experiments

- How To Make A Sconce

- Homemade Phonograph. Continued

- How To Recipes. Part 2

- How To Make A Crossbow And Arrow Sling