Chapter XXIV. (D) Plunger Outlet Basin

Description

This section is from the book "Plumbing And Household Sanitation", by J. Pickering Putnam. Also available from Amazon: Plumbing and household sanitation.

Chapter XXIV. (D) Plunger Outlet Basin

Our plunger outlet basin corresponds with the plunger outlet water closet, and has its defects. A great defect is its several inaccessible fouling chambers. The type may be subdivided into two styles, namely: (1) That having a solid plunger, and (2) that having a hollow plunger.

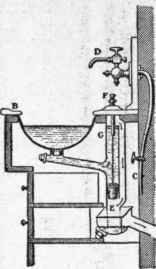

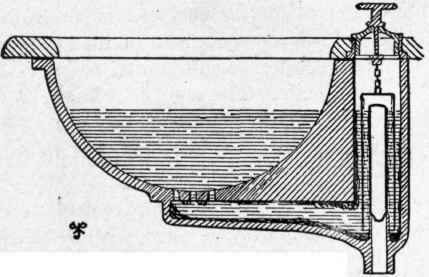

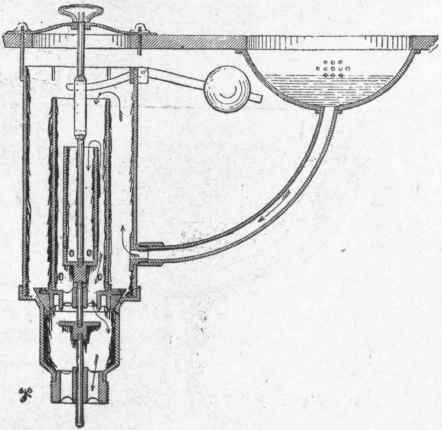

Figure 327 represents the first style. The plunger is supposed to retain the water in the basin by the friction of a packing ring of some elastic material against the inner walls of the plunger chamber. A D-trap appropriately used under the plunger completes a device which, for extent of fouling surface, cannot easily be surpassed. Fig. 328 is an improvement on the last type. There are less fouling surfaces and the outlet passages are made of smooth earthenware. The plunger chamber is made accessible by unscrewing the plate at its top, and the horizontal channel below the strainer is the only part that cannot be reached.

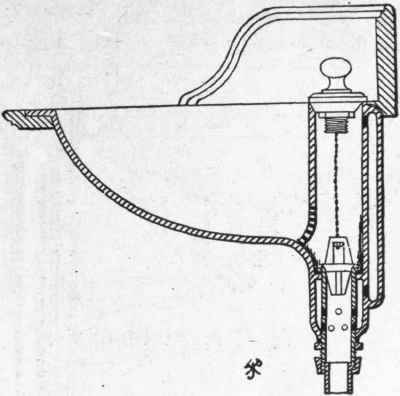

Figure 329 is a still further improvement, inasmuch as the horizontal chamber is done away with by having a perpendicular back to the bowl. The overflow passage is faulty. It should have been constructed after the principle of the preceding fixture, or better still, in the form of a simple standpipe on the plunger. The chief defect, however, is in having the clean water come in contact with the fouled surface of the plunger chamber. The valve should always be placed directly at the outlet opening to avoid this defect.

Fig. 333.

Fig. 327.

Fig. 328.

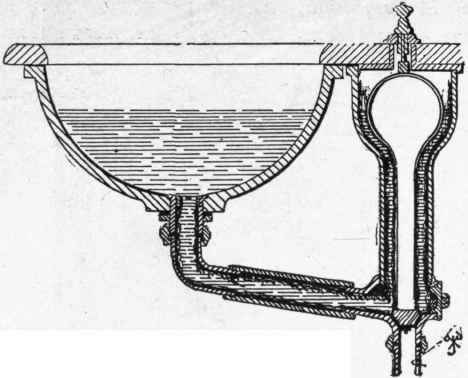

Figure 330 represents the second style of plunger outlet basin in which the plunger is hollow. We have, however, here again the favorite cesspool triply emphasized.

Fig. 329.

Fig. 330.

(e) Floating Plug Outlet Basin.

The object of this device, Figs. 331 and 332, is to do away with the special overflow opening in the basin walls. The plunger or plug has a hollow vessel at the upper end of its stem, and the receiver is enlarged at this point to give room for it. When the water in the basin approaches the point of overflowing, the plunger is buoyed up by the float (the water seeking its level in the plunger and float chamber), and the outlet is opened, letting the superfluous water in the basin escape.

Fig. 331.

Fig. 332.

Fig. 334.

(f) Concealed Standpipe Outlet Basin. The object of this arrangement is the same as the floating plug in the preceding apparatus. It enables the special overflow opening to be dispensed with, the hollow plunger rod serving instead. Figs. 334 to 336 show the stand-pipe as constructed with a metallic chamber.

Fig. 335.

Fig. 336.

Fig. 337.

Fig. 338.

Figure 337 shows a concealed standpipe outlet basin made in all earthenware.

Figure 338 is a very complicated form of concealed stand-pipe Outlet Basin with an enormous amount of fouling surface.

(g) Receiver Outlet Basin.

The principal object of this device is to obtain a quick discharge. It consists of two basins, one within the other, the inner one pivoted, as shown in Fig. 339, in such a manner as to permit it to be revolved by means of a projection on the front edge, raising which empties the entire contents of the basin into a lower basin or receiver. Only half of the receiver is accessible, hence it inevitably becomes foul in use.

Fig. 339. Receiver Outlet Basin.

II. - Basins Having Accessible Overflow Passages.

In this class of fixture every part, both of the basin proper and of its fittings and passages, is visible and easily accessible, and kept clean from top to bottom without unscrewing or undoing any part. We find three subdivisions: (a) the funnel outlet basin; (b) the standpipe outlet basin, and (c) the rear outlet basin.

(a) The Funnel Outlet Basin. Figure 340 illustrates our first subdivision. In general form it is similar to the one just described, but it has the advantage of enabling the entire surface of the lower basin to be reached for cleansing purposes. The interior of the outlet pipe may be inspected and, if desired, periodically cleansed throughout. It is intended that the upper basin should be lifted after use, and the waste water emptied into the lower basin or funnel. In case of overflow, the water runs over the edge of the upper basin and falls into the lower, whence it escapes into the waste pipe. It is evident that to avoid the trouble of lifting the basin it may be provided with lugs or pivots upon which it may be revolved as in the preceding example.

Fig. 340. Funnel Outlet Basin.

Both of these types are altogether faulty in being based on the receiver principle, which also adds greatly to the cost and danger of breaking. The receiver is an entirely unnecessary complication, and the basin has never been largely used in practice except in marine service.

Basins are sometimes provided with a flusning nozzle for connection with the water supply. The flushing device is added to insure a perfectly clean overflow passage whenever the owner sees fit to operate it. A leakage of water-cock at this point would give rise to an unperceived waste of water. This fixture is constructed with a large outlet on the principle of the flush tank, and is in this respect highly to be commended.

(e) The Rear Outlet Basin.

The basin answering all the desiderata I have enumerated at the beginning of this lecture should have an outlet larger than its waste pipe and conveniently operated within the basin itself. It should be absolutely simple, having neither niche, chain nor standpipe, and its overflow passage should be as clean and accessible as any other part of the fixture.

Continue to: