Water-Closets. Part 4

Description

This section is from the book "Standard Practical Plumbing", by R. M. Starbuck. Also available from Amazon: Standard practical plumbing.

Water-Closets. Part 4

In roughing-in the connections for the water-closet, the vertical part of the bend should pass through the floor so that the center will be right to receive the outlet of the fixture. To accomplish this, it is necessary to know the water-closet that is to be used, in order to know how far out the outlet will come. To find the center of the outlet of a water-closet that is in position, be governed by the screw holes on the side of the base. When there is one screw hole on each side of the base, the center of the outlet will usually be opposite these holes. When two holes appear on each side, the center will generally be found midway between them.

After the bend is in position on roughing work, a circular disk of sheet lead should be cut out and soldered into the end of the bend, in order that it may be sealed against the entrance into it of refuse of any kind. If the bend projects through the floor far enough, the end may be mashed in and soldered across the top edge.

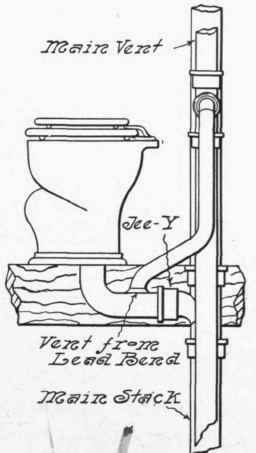

Fig. 137. - Connections of Water-Closet on the Durham System.

In a large majority of cases, the water-closet connection is made into a T-Y fitting, as shown in Fig. 135. It is better to make the connection into a Y fitting and bend, but in most work this is impossible, as such a connection takes up more space than can be allowed, and brings the fixture too far out into the room, as will appear from Fig. 149.

The use of the Y and bend provides the smoothest possible path for the waste, but on vertical stacks, the use of the T-Y is not considered poor practice. It should never be used on horizontal work, however. It often happens in the installation of lines of water-closets in factories, schools, and similar buildings, that the Y and bend can be used to advantage, as shown in Fig. 138. In this work, the vent for each fixture is taken off the short piece of lead pipe, which is used instead of the lead bend. The work shown in Fig. 138 is especially practicable when the building construction and the purposes of the building are such that it is not undesirable to run the horizontal line of soil pipe on the ceiling of the floor below the line of fixtures.

Fig. 138. - Connections for Line of Water-Closets.

If the work cannot be installed as in Fig. 138, the Ys may be used so that their branches point horizontally, in which case a lead bend must be used in connecting each fixture.

In other instances it is desirable to run the horizontal line above the floor. This method necessitates the use of a special form of fixture with its outlet above the floor. If the line of soil pipe is to be exposed to view, it may be supported on special pipe-supporting fittings. These fittings are made to adjust to any pitch at which it is desired to run the pipe. Work of this description may be seen in Fig. 139.

The principles of the venting of water-closets are taken up under the chapter on venting, from which it will be seen that the common method consists in taking it off the lead bend, as in Fig. 141. The venting of water-closets from the bowl itself, as in Fig.

Fig. 139. - Soil Pipe for Line of Water-Closets Supported by Supporting Fittings.

Fig. 140. - Water-Closet Vented from the Bowl.

Fig. 141. - Ordinary Method of Venting Water-Closets.

Fig. 142. - Water-Closet Vented from T-Y.

140, is no longer considered good practice. In addition to the regular method of venting, special waste fittings provided with vent openings are now much used, one of the simplest of these appearing in Fig. 142.

Continue to: