55. The Teeth Of Cross-Cutting-Saws

Description

This section is from the book "Bench Work In Wood", by W. F. M. Goss. Also available from Amazon: Bench Work In Wood.

55. The Teeth Of Cross-Cutting-Saws

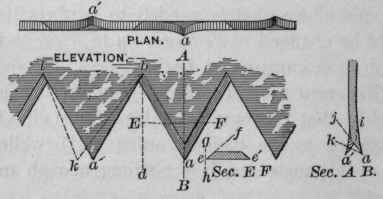

The Teeth Of Cross-Cutting-Saws. If a ripping-saw is used directly across the grain, the fibers of the material will be torn from each other without being properly cut; hence the necessity for a saw that will "crosscut." Fig. 64 shows by its three views a representative form of tooth for this saw. It will be seen by the figure that the tooth terminates in a trianFig. 64 gular point; and also, that while the point a is formed on one side of the blade, the next, a' is formed on the opposite side; thus throughout its length, the points of any two adjacent teeth being on opposite sides of the blade. This arrangement makes the end view of the blade show two parallel lines of points, and between them a triangular depression, which, when exaggerated by the "set," will appear as shown by section AB,In action, the points a and a', Fig. 65, score the work, and the friction between the teeth and the cut fibers breaks up the latter, and they are carried off by the saw.

Fig. 64.

Assuming that it is a matter of convenience to have these teeth, as well as those of the ripping-saw, equal to the space between any two of them, there are three questions which may be considered concerning their proportions. First, what shall be the inclination of the advancing edge or "face" of the tooth, as represented by the line ab compared with the line bd, Fig. 64? Holly, in his little work on "The Art of Saw-Filing," shows the similarity of action between the advancing edge ab and the edge of a pocket knife when made to cut across the grain, and asserts that a knife with its cutting edge perpendicular to the surface upon which it acts (a position equivalent to bd) will make a rougher cut, and require more force to carry it forward at a given depth, than when it is inclined in a position similar to that of the line ab. The result obtained from such an experiment cannot be regarded as conclusive, because of the great difference in the character of the cutting edges compared. But, if it is found that the knife with its keen cutting edge behaves more satisfactorily at an inclination to the work, it seems reasonable to conclude that the rougher edge of a saw tooth will give the best results when much more inclined. A consideration of these points justifies the belief that an angle of 60 degrees with the work, that is, with a line passing through the points a' and a, is none too great, and all practice goes to show that teeth so formed not only do very smooth work, but cut with ease and rapidity.

Fig. 65

Secondly, what shall be the angle of the advancing face of the tooth, as represented by lines e'e and ef, Sec. EF, Fig. 64? Since this angle forms the cutting wedge of the tooth, it should be as acute as is consistent with strength. Greater strength being required for action in hard wood than in soft, it follows that this angle should be varied with the material in which it is used. For general work it may correspond to the angle e'ef.

Thirdly, what shall be the acuteness of the point as indicated by the angle iaj, Sec. AB, Fig. 64? This, also, is determined by the character of the material to be cut. It should be more obtuse, as iak, for hard wood than for soft wood, not only because additional strength is required, but also because, if too acute, the scoring will be done so easily that the fibers between the scores will not break out, and the saw, being unable to pass down into new work, will slide along on the old.

Fig. 66

Fig. 67

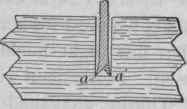

Under such conditions, the bottom of the kerf will appear as shown by Fig. 66. A more obtuse angle will not penetrate the work so readily, but it will break up the fibers better, and thus leave the kerf in proper form as shown by Fig. 67. The softer woods break out more easily than the harder ones, and, consequently, a keener point may be used in working in them.

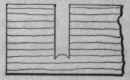

56. The Back-Saw is used only where accurate cuts are required. Its teeth, in form, are similar to those of the crosscutting-saw, except that the line of the advancing face is brought forward as indicated by bkl, Fig. 64, to increase their efficiency when used with the grain. They are, however, much finer, there being usually as many as sixteen to the inch. This saw cuts slowly as compared with a panel-saw, but may be used in very delicate work. It is used to cut in any direction relative to the grain of the wood. The bur left by the file after sharpening, forms a sufficient set.

The blade A, Fig. 68, is in itself too thin to withstand the thrust necessary to drive it into the work, and is strengthened by an iron "back," B. This, being thicker than the blade, will not allow the saw to penetrate beyond a depth represented by the distance C. For this reason the blade is uniform in width instead of tapering.

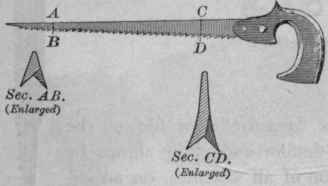

57. The Compass-Saw, shown by Fig. 69, is intended for sawing in curved lines. Its blade is extremely thick, and the teeth are given an enormous amount of set. See sections AB and CD, Fig. 69. If the curve in which it is to be used is very small, only a short portion of the blade's length next the point can be used. With a curve of longer radius, a greater length of blade may be brought into action.

Its teeth are of the form shown by Fig. 70, having the square face of the ripping-saw, and the point of the cross-cutting-saw.

Fig. 68

Fig. 69

Fig. 70

They are thus adapted for use in any direction relative to the grain of the wood.

Appliances for Saw Filing and Setting.

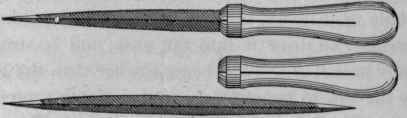

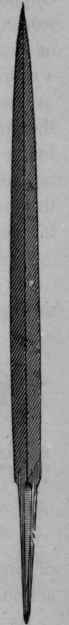

58. A "Triangular Saw File"1 is of the form shown by Fig. 71. A "slim" saw file is represented by Fig. 72; it is two inches longer than a "regular" saw file of the same cross-section. A "double ender" is shown by Fig. 73, and a cross-section of all saw files, on an enlarged scale, by Fig. 74.

Fig. 71

Regular.

Fig. 73

Fig. 74

Fig. 72

Slim.

Continue to: