Metal-Turning With Hand Tools. Continued

Description

This section is from the book "Turning Lathes", by James Lukin. Also available from Amazon: Turning Lathes: A Guide to Turning, Screw Cutting, Metal Spinning and Ornamental Turning.

Metal-Turning With Hand Tools. Continued

As regards speed for metal-turning, it may be briefly stated here that cast iron needs a very slow speed, and this is best obtained by back gear, which is very useful also for boring metal. But wrought iron of small size may be turned by means of the slowest speed on the flywheel, and brass can be cut upon the next speed, or the first on the rim of the wheel. Small brasswork, indeed, may be turned at the same speed as hard wood. The finishing touch is given to brass by a planisher, as it is called, which is, in fact, a flat tool, thin at the edge, and ground off square; and if this tool is rubbed with a burnisher after being ground and set, it will in turn, not only cut the metal, but leave upon it a burnished surface, which looks exceedingly well on any fillets or beads which form rings above the general surface. These may also be finished with the milling tool, which acts by pressure, and impresses its own pattern on the work while revolving in close contact with it. Heads of screws to be turned by the finger and thumb are nearly always thus finished, as the minute teeth so formed produce a rough surface, not liable to slip when laid hold of. There is one vexatious tendency in brass which often causes trouble - namely, its tendency to chatter or vibrate under the action of the tool. This causes a series of striae, or minute undulations, to be cut on its surface, which, once begun, are difficult to check. The only way to prevent the mischief appears to be to move the tool ceaselessly, so as to alter the direction of the vibrations constantly, thereby counteracting them. A similar result may be attained by a pad of sole leather on the rest, or by allowing the tool to bed itself partially against the thumb and finger. But short cuts, with the tool slightly tilted, and frequently altered in position, are the most general antidotes. It is, however, often necessary to go over the whole surface with a router, or round-end tool, to get rid of striae formed in a few seconds. Some kinds of brass are more subject to this tendency than others.

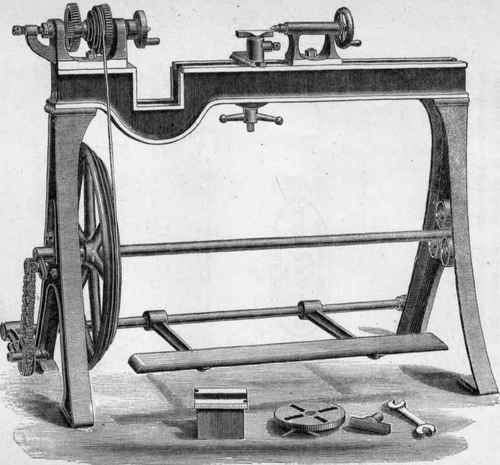

PLATE X.- BACK-GEARED LATHE, WITH GAP FOR METAL.

(Made by Britannia Co,

Continue to: