The Self-Acting Lathe. Part 2

Description

This section is from the book "Turning Lathes", by James Lukin. Also available from Amazon: Turning Lathes: A Guide to Turning, Screw Cutting, Metal Spinning and Ornamental Turning.

The Self-Acting Lathe. Part 2

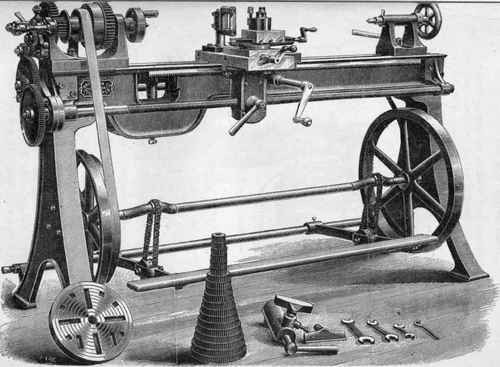

The tools required are the same as those already described, and either the solid ones can be used, or the cutter bar; but when once set into cut, nothing is needed but to work the treadle, when the tool will be carried along with a perfectly even motion, such as no hand feed can rival. Among Lathe novelties introduced by the Britannia Company, of Colchester, two are well worthy of notice, and they may be taken as extremes of power - viz., their Nos. 13 and 18: the first a small screw-cutting Lathe of 3in. centre only, with 2ft. 6in. or 3ft. bed; and the other a treble-geared Lathe, specially made for the Admiralty for use on shipboard - a Lathe with gap bed, to swing 24in., and with power enough, under treadle action alone, to take a ½in. cut off a 2in. or 3in. bar. It would be hard to find a tool of such power more compact, better designed, or better made; and the price - £36 for one of 5in. centre - is marvellously low. That it is possible to turn a pump-cover, or similar article, 24in. diameter, by foot power is, at first sight, incredible; but the treble gear multiplies enormously the power applied. This Lathe is illustrated here in Fig. 21, which gives a good idea of its general appearance. In a country fitting-shop or agricultural implement maker's where steam is not available, this Lathe would be invaluable.

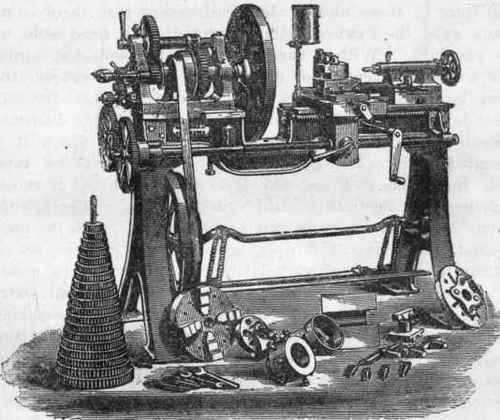

PLATE XII. - LARGE SELF-ACTING AND SCREW-CUTTING LATHE.

(No. 16 Lathe, by Britannia Company).

Fig. 21. - Treble-Geared Lathe.

The No. 13 (see Plate XIII.) is the amateur's Lathe par excellence for all light work in engineering, such as model-making and the construction of electrical and scientific instruments. Fitted also, however, with overhead, as shown here, it becomes suitable for ornamental and plain turning in wood or ivory. As a screw-cutting Lathe, it is an exact miniature of those already described, except that there is no crank axle, the. flywheel being mounted on a fixed stud on the standard. "With a handle fitted to the slide-rest screw, and a revolving cutter or drill, driven by the overhead, the most beautiful spiral work can be done. When the gap piece is out of the bed, it will admit a disc of l0 ½in. diameter, instead of 6in. The drawer in the table on which it is mounted is intended for spanners, tommies, mandrel taps, and such like. Price £15 15s.; or £21 with overhead, including the ornamental drill spindle. This Lathe is such as an ingenious amateur can hardly fail to turn to good account, removing, as it does, both the difficulty of screw-cutting, and also of highly-finished plain turning in metal. It can be made with a crank shaft at a small extra charge. "With castings, now so easily obtained, engine-making should become, by the help of this unique Lathe, comparatively easy work. The overhead is, moreover, an advantage that need only be tried to be appreciated, especially in cutting screws in wood. These can be beautifully cut with small, revolving cutters, which make a clean thread far better than is attainable with a fixed tool, owing to the very slow motion of the mandrel, which is not well suited for wood. In fact, wood cannot revolve too quickly against the tool, especially if it is of the kind known as soft wood. A V tool, however, will cut the latter quite cleanly, and make a nice thread, and this can be held in a cutter bar, and fixed on the slide-rest of this Lathe.

It is not to be supposed that the amateur, or anyone not a thorough adept, will succeed in either plain turning or screw-cutting - most decidedly not the latter - merely by obtaining one of these handy little machines. A screw-cutting Lathe is a very ingenious bit of mechanism, and its capabilities are not to be learnt in a day. When, therefore, it first comes to hand, it should be thoroughly examined, and its various parts studied until well understood. Let the various wheels be mounted - first, a mere idle wheel, or the stud brought into gear with that or the screw, and with the small one below the two that are on a pivoted plate at the back of the headstock, which two, I have explained, are meant to reverse the motion of the screw for cutting left-handed threads. Then, when the single row of wheels has been thoroughly understood, let the wheel and pinion on the sleeve be mounted on the stud, and the effect of this arrangement tested as regards change of speed. Put a cylinder of wood in the Lathe, to experiment upon; and, with a sharp point tool, try the result of different wheels geared singly and also doubly. This will teach, better than any written description, the nature of screw-cutting, to be hereafter carried out, in metal. It will be found that wheels geared singly - i.e., in one plane - only produce the effect of the first and last; the result, as regards speed, being the same as if these were geared together. But the intermediate one alters the direction of motion, and is necessary to fill up the space between the mandrel wheel and that on the leading screw. Any intermediate wheel that is of suitable size may, therefore, be used indifferently, without altering the ratio of speed between the screw and mandrel. In illustration of this, suppose a wheel of sixty teeth on the screw, and one of ten on the mandrel, which is the driver or originator of the motion: it is evident that the rate will be six to one - that is to say, the small wheel will turn six times while the large wheel turns once - and they will turn in opposite directions. Insert between them one of twenty teeth, which will, at the same time, reverse the direction of the driven wheel. The ten wheel (driver) makes one turn, while the twenty on the stud makes half a turn - i.e., uses ten of its teeth - and, as six times ten are sixty - the number of teeth on the screw wheel - the latter still makes, as before, six turns, to one of the driver. Instead of an intermediate wheel of twenty cogs, any other will answer equally well that may be of convenient size. The small wheel under the pair on the plate is of the same size as that on the mandrel, and consequently may be considered the mandrel wheel. Consequently, the wheel placed on its projecting axle may be reckoned as being placed upon the mandrel itself, and is to be considered the first driver of the train. Screw-cutting depends upon the rate at which the slide-rest carrying the tool travels compared with that at which the work revolves. The leading screw is of half or quarter pitch - two or four threads to the inch - the latter in all small Lathes; so that one turn of the screw moves the rest ¼in. along the bed. If the wheels are so arranged, therefore, as to carry the mandrel once round in the same time as the tool takes to travel ¼in., or four times while the tool travels l in., the screw cut will be quarter pitch also - the same as the original leading screw. Here the mandrel and screw make turn for turn, and, therefore, each will need a wheel of equal number of teeth, and to fill up the space, any idle wheel may be placed on the stud.

Continue to: