Screw Cutting

Description

This section is from the book "Machine Shop Work", by Frederick W. Turner, Oscar E. Perrigo, Howard P. Fairfield. Also available from Amazon: Machine shop work.

Screw Cutting

The tools used for cutting threads are called screw-cutting tools. These tools are used in the lathe in the same manner as the diamond-point and round-nosed tools. The cutting edge of the tool must be of the same contour as the space between the finished threads.

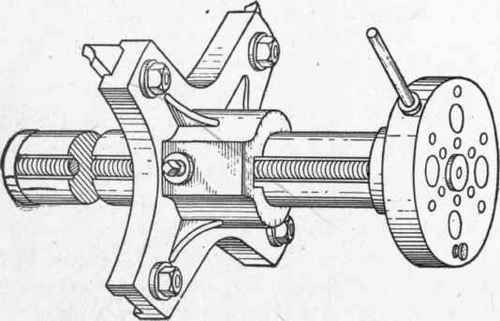

Fig. 154. Boring Head.

Types of Threads

There are five types of screw-threads commonly used in this country: the V-thread, shown in Fig. 155, has the form of an equilateral triangle, with an angle of 60 degrees. It is sharp at the top and bottom. This thread is difficult to cut, because of the trouble experienced in keeping the point of the tool sharp.

The Sellers, Franklin Institute, or United States Standard is a modified form of V-thread, shown in Fig. 156. This thread has an angle of 60 degrees, with the top and bottom flattened for one-eighth of its depth.

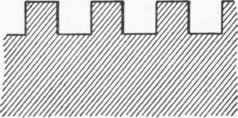

Another form in common use is the square thread, shown in Fig. 157. The thread and space are of the same width. This thread is used where heavy work is done, such as in jack-screws and presses.

Fig. 155. Section of V-Thread.

Fig. 156. Sellers, Franklin Institute, or United Stated Standard Thread.

The Whitworth thread is similar to the United States Standard, the slight differences being as follows: the sides form an angle of 55 degrees instead of 60 degrees, and the top and bottom are rounded instead of flat.

The fifth type, the Acme thread, is somewhat similar to the square form. The difference is that the sides incline 14 1/2| degrees from those of the square thread. This form of thread is much used for lathe lead-screws and for giving motion to sliding parts of fine instruments, because the thread is simpler to construct than the square form, and the lost

Fig. 157. Square Thread.

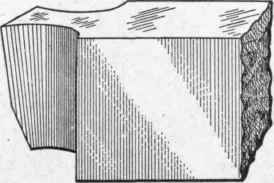

Fig. 158. Side View of Tool for Cutting Square Threads.

Fig. 159..

Square Thread

Tool Showing

Inclination of

Thread to Body motion can be taken up by simply closing the nut halves nearer together.

Continue to: