Boring Machines. Continued

Description

This section is from the book "The Engineer's And Mechanic's Encyclopaedia", by Luke Hebert. Also available from Amazon: Engineer's And Mechanic's Encyclopaedia.

Boring Machines. Continued

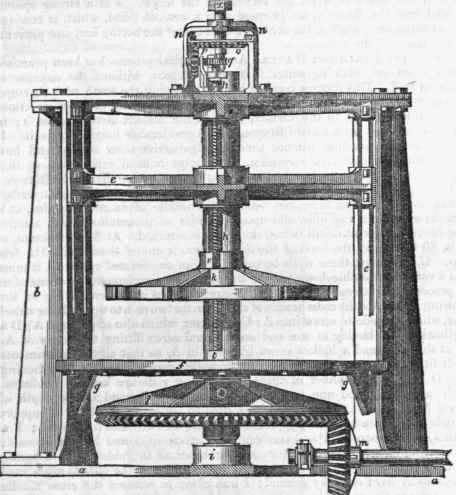

On the periphery of the block are eight notches, in which the cutters are fixed by wedges; l a bevelled wheel, and m a pinion by which a rotatory motion is given to the boring bar and cutter block, the latter being made to advance along the former by the following means: Upon the top plate d is a small triangular frame n, to which is bolted the bevelled wheel o, in which another wheel p geers. p revolves in bearings fixed upon the head of the boring bar, and has upon its axis an endless screw driving the worm-wheel q, which is fixed upon a long screw r, lying in a mortise cut in one side of the boring bar. This screw turns in collars i and t, and works in a nut fitting into the mortise in the boring bar, and attached to the cutter block at v; the bevelled wheel p is 10 inches in diameter, and the wheel o 16 inches; therefore in ten revolutions of the boring bar, the wheel p will perform sixteen revolutions on its axis, and at each revolution the endless screw upon its axis will move the worm wheel q one tooth forward; and as the worm wheel has sixteen teeth, in ten revolutions of the boring bar the screw r, to which the worm wheel is attached, will make one turn, and will advance the cutter block through a space equal to the space between the threads of the screw, x is a strong spindle screwed into the frame n, and formed with a conical point, which is received into a conical steel bush in the centre of the head of the boring bar, and prevents the bar from rising.

Fig. 1.

Fig. 2.

Boring the Earth for Water. An economical process has been practised of late years for obtaining water from great depths, without the expense of sinking a well. This process consists simply in boring the earth with an auger and other proper instruments, to a considerable depth; and in most situations water will flow either to the surface, or to within a short distance from it; in some places it has been known to spout to a considerable height above it. It has long been a question whence these springs derive their supply, and how they acquire the power of ascension. The most natural supposition is, that they are connected by subterraneous channels with some elevated reservoir; but this explanation is not altogether free from difficulty. These "Artesian wells," as they are termed, are to be met with in the middle of extensive plains, at a great distance from any hills, and upon the sides of mountains, which require to be bored to a great depth before the water is attained. At Mount Rouge, at Paris, 80 feet above the level of the Seine, there is one of these wells 315 feet deep.

If, therefore, these wells be supplied from an elevated reservoir, it must lie at a very considerable distance from the wells.

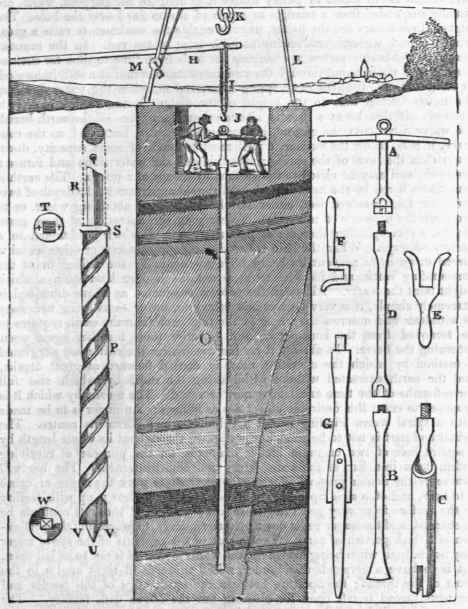

The implements made use of in the process are extremely simple, and are represented in the engraving on the following page. A is the cross handle of the borer, for two men to work; B the chisel borer, which is made to screw into A; C the auger, which also screws into A; D a lengthening rod, having at one end an external screw fitting the screw of A, and at the other end a hollow screw like that in A, so that all the instruments which fit into A may, as occasion requires, be screwed into the lengthening piece D. A great number of these lengthening rods are kept in readiness, which can be screwed one into the other, so as to descend to the depth of several hundred feet. E a forked iron, used to lay across the hole to support the rods at the joints, while the pieces are being screwed and unscrewed; F a spanner, used to screw on and unscrew the various tools and lengths of rods, G a clearing chisel, with a probe or piercer attached to guide it; H a spring bar, used to produce a vibrating up-and-down motion to the chisel, when used to peck away hard or rocky ground; l iron chain to connect the cross handle of the tools to the spring bar; J two men at work, boring with the chisel; K the lower pulley of a pair of blocks, suspended to a pair of shears or a triangle above; L the shears or compasses; M winch or crane, to work the blocks when great weights are to be raised; O three lengths of rods, and the chisel in the act of boring, - perforation about 42 feet.

As a preparatory measure, a large hole is usually dug to the depth of seven or eight feet; at the bottom of which a floor is formed, by means of some planks, for the men to stand on and pace round whilst using the instruments. If the earth is very soft, the only tool requisite is the auger C of three or four inches diameter, which is screwed into the cross handle A, and the perforation is easily effected by the mere turning of it round by two men, as shewn in the drawing. When the auger has penetrated to nearly the depth of the tube, it is withdrawn, and cleared of its contents. It is then let down again, and the perforation is in this manner continued to the whole length of the instrument. To proceed to a greater depth, the lengthening rods, before described, are put in requisition. The auger is detached from the handle by unscrewing it; a piece of rod D is screwed in its place, and the auger screwed on to the rod. With the instrument thus lengthened seven or eight feet, the boring is renewed by means of the auger, as long as the earth is found to be sufficiently soft and yielding. Whenever it proves otherwise, or hard and rocky, the auger is detached from the rod, and the chisel B, which is from three to four inches in diameter at its edges, is screwed on in its place.

If the ground is not very hard, the boring may be continued by the chisel, by the workmen pressing upon it as they turn it round; but when the earth is too hard to be operated upon by a chisel in this way, recourse is had to pecking, which is done by lifting up the instrument, and striking it against the opposing substance till it is chipped away, or reduced to powder to a certain depth. The rod and chisel are then again drawn up, and the auger substituted for the chisel, for the purpose of extracting the pulverized stony matter contained in the hole. The chisel and auger are thus employed alternately where the ground is hard and stony, the one for chipping away or pulverizing, and the other for clearing out As the perforation deepens, the process of pecking becomes very laborious; recourse is therefore had to the spring bar H, which is a strong pole placed horizontally over the well, at the height of three or four feet from the ground, with one end inserted into a post or other stronghold. The chain l is attached to this bar, and the borer is suspended by the handle to the hook of the chain which supports its weight; a slight vertical motion is then given to the bar by the workmen, which causes the chisel to peck away with great rapidity.

As the weight of the implements becomes too great to be drawn up by hand, when the boring has proceeded to a great depth, the mechanical aid of a pair of pulley blocks K is used for the purpose, which are usually suspended from a triangle or a pair of shears fixed over the hole. The higher these shears are the better, so as to enable the workmen to raise a great length of rod, without unscrewing at each joint of the rod. In the manner described the boring proceeds, changing the tools from time to time for such as may be best suited to cut through the various strata, whether of a soft, indurated, or stony texture, until the main spring is arrived at, when the water flows up the newly-formed tube to the height of the distant spring from which it is derived. If that be at a greater altitude than the surface of the earth bored, the water rises above the ground, producing a perpetual fountain; on the contrary, if it be below the surface, a well must be sunk of some capacity, down lower than the level of the spring; into this well the water flows and forms a reservoir, and may be raised to the surface by means of a pump.

The earth is sometimes bored by the before-mentioned simple apparatus to the depth of two, three, or four hundred feet, either for the purpose of obtaining water, or to ascertain the presence of minerals. To carry on the operation at these great depths, a corresponding increase of power is required, which is obtained in a variety of ways. When the hole is bored, a pipe of cast iron or other metal is forced down it, to prevent its being filled up again by the falling in of the surrounding earth, and likewise to keep out the impure land springs which might taint the water. Although the process conducted as above described is extremely simple, it is very tedious and laborious, owing to its being necessary to withdraw and unscrew the whole of the rods each time the earth requires to be removed from the boring tool, and to screw them together again upon returning the borer. To obviate these inconveniences the editor has suggested a method by which the operation may be carried forward at great depths, and the earth extracted without withdrawing the rods, by which also full three-fourths of the time and labour may be saved.

The means by which it is proposed to effect this desirable object are as follows: An auger is to be made with a spiral worm winding round a cylinder which forms its centre. The cylindrical part is not to be solid, but perforated throughout its whole length by a square hole of two or more inches diameter, for the purpose of receiving within it an iron bar of the same figure and admeasurement. The bar will thus serve the double purpose of a spindle or shaft to work the auger or cause it to bore, and of a slide upon which the auger may be drawn up with facility to the surface from very great depths in a few seconds of time, its contents be discharged, and the auger be let down again as quickly, to proceed in the perforation of a fresh portion of earth. That a part of the contents of the spiral auger may not fall out when being drawn up, the worm or thread is not to be left open, but is to have a perpendicular border, raised upwards at right angles to the plane of the thread; the aperture between the upper edge of this border and the next thread is left open for clearing out the auger with facility.

The construction will be easily understood by referring to the engraving, in which P represents the exterior of the spiral worm or auger; Q the square iron bar passing through the square tube of the auger; R chains to draw up the spiral worm along the bar; S top plate, to which the chains are attached; T upper view of the plate, showing the square hole through which the bar passes; U angular point of the square bar; V V cutting edges of the auger; W under side view of the bottom cutting parts of the auger. Various kinds of tools may be attached to the bottom of this auger so as to peck, etc.

Continue to: