398. Cutting, Bending And Riveting Tools

Description

This section is from the book "An Elementary Outline Of Mechanical Processes", by G. W. Danforth. Also available from Amazon: An elementary outline of mechanical processes.

398. Cutting, Bending And Riveting Tools

The principal tools for these uses are as follows:

(1) Bench shears. These are used for heavier cutting and are supported while in use by placing the bend of the lower handle in a square hole in the bench. See Fig. 245.

(2) Snips, or hand shears. Fig. 246.

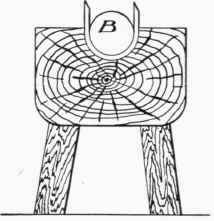

(3) Forming machine. This is a small set of bending rolls used for bending sheets into cylindrical form as described in boiler-shop work. These rolls are seldom longer than 3 feet, hence for bending longer sheets, a bending block is used, the end view of which is shown in Fig. 247. The solid iron mandrel B bends the sheet and the projecting edges are then beaten over it with wood mallets.

Fig. 247. - Bending Block.

(4) Tinners' stakes. These tools are anvils for sheet-metal workers. Fig. 248 shows a few of the many designs. They are supported in a square hole in the bench.

(5) Mandrels. These are long round bars of iron. One end is clamped down against the back edge of the bench top and the other end projects out horizontally two or more feet beyond the bench for use as an anvil in shaping work.

Fig. 248. - Tinners' Stakes.

(6) Expanders. These are very similar to a boiler-tube expander.

They are used to expand a copper pipe slightly for about 3 inches from the end for fitting two pipes together in a cup joint. An efficient expander may be easily made of a sleeve coupling (pipefitting) screwed on the end of a short piece of iron pipe. This coupling is driven into the end of the pipe to he expanded.

(7) Drift set. This tool is shown in Fig. 249, No. 3, and is used to set the metal of the fillet d, Fig. 256, against the inner pipe to make a close-fitting joint preparatory to brazing the joint.

(8) Collar lifters. These tools (Nos. 1 and 2, Fig. 249) are used to enlarge a small hole drilled through the wall of a copper pipe as an opening for a branch outlet. Their use is shown in Fig. 257.

Fig. 249. - Coppersmith Tools.

(9) Burring machine. This machine is placed on the bench and operated by a crank. Its small disc rollers or "faces" turn a burr or flange on the end of a thin hollow cylinder, as a can end, and on the edge of a disc of metal to form a bottom.

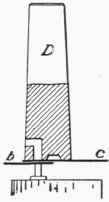

Fig. 250. - Rivet Set.

(10) Beading machine. This is another small portable bench machine. It rolls different designs of corrugations around the body of a pipe near the open end. These corrugations, are usually seen as fancy rings on stove pipes or sheet-metal utensils, and they serve the purpose of stiffening the walls of the pipe.

(11) Rivet set. This set is used as shown in Fig. 250. The edges of two sheets of metal b and c are placed over the rivet as shown. The set D is so placed that when struck with a hammer the rivet will punch a hole through the metal. The set is then shifted to place the small cone-head depression over the rivet end, and a blow of the hammer sets the end down to the form of the depression.

(12) Pipe bender. This machine is made in many forms by different makers. Fig. 251 shows a diagram of a machine adapted to cold bending of wrought iron or other pipes up to 2-inch diameter when using steam or compressed air. A hydraulic machine can bend larger pipes. A die B is carried on the end of a piston rod C, and another die D rests solidly on the frame of the machine. The pipe is slowly bent as B travels toward D. The grooves in B and D must exactly fit the size of pipe to be bent to keep the pipe from flattening out of round as it bends.

Fig. 251. - Pipe-Bending Machine.

Fig. 252. - Coppersmith Hammers.

Continue to: