Milling In The Lathe

Description

This section is from the book "Lathe Design, Construction And Operation, With Practical Examples Of The Lathe Work", by Oscar E. Perrigo. Also available from Amazon: Lathe Design: Construction And Operation.

Milling In The Lathe

A number of milling attachments for use with the lathe have been offered, some of which are very practical, others that are not so good. A carefully designed and well constructed attachment of this nature is clearly shown at Fig. 324 doing various grades of milling work. This is built by the South Bend Lathe Works and while made for lathes of their manufacture it is equally valuable on other lathes of similar design. The attachment is fitted to the top of the carriage taking the place of the upper portion of the compound rest. It is located by a dowel pin or centering pin projecting from the base. The fixture is fastened to the compound rest with two bolts, in just the same way as the compound rest upper portion is fastened. The milling attachment is specially valuable for the small shop as it permits one to use the lathe for various jobs that ordinarily could be done only with a shaper or milling machine. As an attachment of this kind swivels all the way around on a horizontal plane and is graduated in degrees, as well as permitting it to be swiveled in a vertical plane, many forms of work can be economically performed. The vertical adjusting screw has a graduated collar reading in one thousandths of an inch thus making the attachment suitable for fine work as well as a large variety of work.

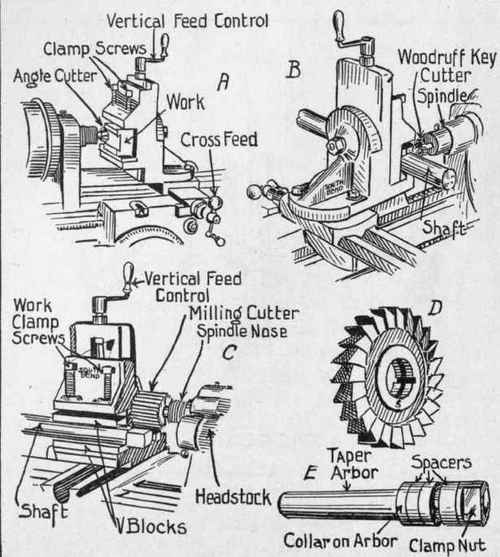

The illustration at Fig. 324-A shows the use of an angle milling cutter in forming a piece of cast iron held in the vise of the milling fixture. The length of the cut is controlled by the cross feed screw, the depth by the adjustment of the lathe carriage and the vertical adjustment governed by the vertical screw of the attachment. At B, the attachment is shown holding a steel shaft that is being keyseated for a Woodruff key. The view at C shows the method of milling a square on a shaft. The same method can be used to cut off shafting or tubing by substituting a saw for a milling cutter. The usual form of milling cutter shown at D is used in connection with the special arbor at E which is made to fit the taper hole in the head spindle of the lathe. Any milling cutter may be used, the form depending upon the character of the piece to be machined.

The Barnes Milling Attachment shown at Fig. 325 can be conveniently secured to any lathe and is adapted to all classes of the most accurate milling and gear cutting. It is practically a universal attachment and can do any work that can be done on a milling machine of equivalent capacity. It will make milling cutters, can be used for fluting taps and reamers, for cutting spur and bevel gears, for surface milling, slotting, etc. The cutter block is attached to the cross slide of the lathe carriage, can be moved in or out and the cutter can be adjusted up and down on the arbor to accommodate work. The universal head is clamped to the inside ways of the lathe bed and has longitudinal, cross and vertical slides. The feed screws are graduated to read in thousandths of an inch and the vertical and horizontal swivels are graduated 180 degrees, this permitting very accurate adjustments and cuts to be made at any angle. Either power feed or hand crank on apron may be used to feed cutter to work and longitudinal feed of universal head may be used to increase length of feed. The spindle of the universal head can be supplied fitted with a draw in chuck attachment. The device will cut gears as large as the lathe will swing. A complete index is furnished and it is said that all numbers of teeth can be cut from 1 to 50 and nearly all up to 360. Standard milling cutters are used. The following specifications give some idea of the size of the attachment.

Fig. 324. - The South Bend Milling Attachment and Its Use.

Fig. 325. - The Barnes Milling Attachment.

Longitudinal Feed.................................. | 4 3/4" |

Cross Feed...................................... | 10 1/2" |

Vertical Feed............... | 4 3/4" |

Travel of Cutter.................. | 3 1/2" |

Distance between Centers of Spindle and Overhanging Arm............................ | 9" |

Swing on Centers between Overhanging Arm..... | 4 1/2" |

Distance between Vise Jaws................... | 2 5/8" |

Size of Vise Jaws............................. | 4 1/4" x 1 |

Diameter of Arbor............................ | 7/8" |

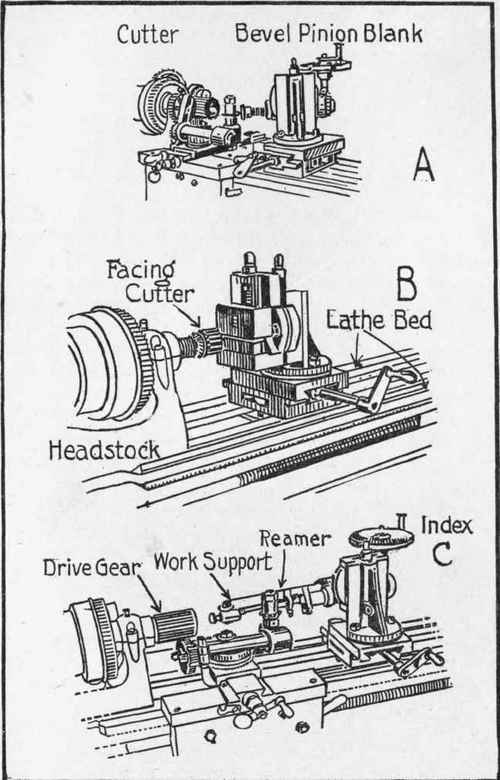

The views at Fig. 326 show the practical application of the device to a variety of work. Fig. 325 shows the general construction very clearly. The cutter is driven by spur and spiral gears. A driving gear is attached to the lathe spindle, this serving to transmit motion through an idler gear to a small gear mounted at one end of the enclosed cutter drive shaft. The shaft carries a spiral gear at the cutter end of the housing and drives the cutter spindle through the spiral gear at its lower end. The view at Fig. 326-A shows the method of milling a bevel pinion. At B the gear cutting attachment is removed and a vise is supplied to hold work machined by a facing cutter driven directly from the lathe spindle. The view at C shows the attachment rigged up for milling flutes in a reamer. Obviously a device of the character will prove very valuable in any small machine shop where a regular universal milling machine is not available.

Another milling attachment for lathes is shown at Fig. 327. This is made by the Cincinnati Pulley Machine Company and is capable of using standard cutters and doing such work as Woodruff keyseats, keyways, surface and end milling, slotting, etc. The machine is furnished with a 1/4 H. P. motor which is geared to a worm gear driving the cutter spindle so the ratio of 72 to 1 gives ample power for all average work. The motor is attached to any lamp socket by cord and is then ready to operate.

They are furnished for either direct or alternating current and wound for either 110 or 220 volts. The spindle is made of high carbon steel and runs in bronze bearings. The worm is of steel, hardened and ground. The worm wheel is made of bronze. The worm and worm wheel runs in an oil container, the cover of which is removed in illustrations to show gearing. Annular ball bearings are employed on both worm and worm gear shafts to reduce friction. The illustrations show very clearly the round column on which the sliding arm is carried. This arm is provided with a vertical adjustment to raise or lower the cutter according to the work to be done. The vertical screw connected with the arm permits micrometer adjustment. Cross and longitudinal adjustment is taken care of by the carriage and cross feed movements of the lathe. The cutter in illustration A is milling a squared shaft and various samples of work that can be done with the device are also shown here. The desired longitudinal movement of the cutter is obtained by hand movement of the lathe carriage. The shaft is supported by the lathe chuck and tail stock center. In the view B the cutter is shown at work on a male driving clutch member which is supported by the lathe chuck. The method of using the attachment is clearly shown in illustrations. An indexing mechanism is also furnished by the makers to permit the device to cut gears. The driving motor speed is 1700 R. P. M., the cutter spindle speed is 24 R. P. M.

Fig. 32b. - Outlining Some Practical Applications of the Barnes Milling Attachment for Lathes.

Continue to: