Steel Construction Problems For Practice

Description

This section is from the book "Cyclopedia Of Architecture, Carpentry, And Building", by James C. et al. Also available from Amazon: Cyclopedia Of Architecture, Carpentry And Building.

Steel Construction Problems For Practice

1. Given a 15-inch 60-lb. beam on a span, center to center of bearings, of 22 feet 6 inches. Required the safe load uniformly distributed at a fibre stress of 16,000 lbs. per square inch.

UNTELS TYPE A Fig 90.

Solve (a), by the methods given above;

(6), by use of coefficient of strength given in table of

Properties by the formula M = C/8.

2. Find from the table of Safe Loads the total load which a 6-inch 12.25-lb. beam will carry on an effective span of 15 feet, without exceeding the limits of deflection for plastered ceiling; allowable fibre strain 16,000 lbs. per square inch.

What would be the safe load in the above problem if the allowable fibre strain were 10,000 lbs. per square inch? In the following problems, solve,

(a) by use of tables of Safe Loads, and

(5) by formula M = fI/y, and use of table of Properties.

3. Find the greatest safe load in pounds uniformly distributed that will be sustained by a 10-inch 35-lb. I beam having a clear span of 10 feet 3 inches and an effective span of 11 feet 3 inches, the allowed stress in extreme fibre being 12,500.

4. The moment of the forces in foot-pounds acting on a beam of undetermined size is 108,000. What size of beam will be required if a stress of 16,000 pounds per square inch is allowed in extreme fibre?

5. What load uniformly distributed will a 15-inch 42-lb. I beam support per linear foot, if the span, center to center of bearings, is 10 feet 4 inches, and the allowed stress in extreme fibre is 14,500 pounds per square inch?

6. What weight of wall will a 12-inch 31.5-lb. I beam 18 feet long between center of bearings carry, no transverse support for wall? Allowable fibre strain, 16,000 lbs. per square inch.

7. An office building has columns spaced 15 feet on center in both directions. Give in detail the estimates of dead load for the following constructions. Live load in each case 100 lbs. per square foot.

(a) Beams spaced 5 feet center to center, 8-inch terra cotta arch of end construction, 2-inch wood screeds and cinder concrete filling, 7/8-inch under floor, and 7/8-inch maple top floor.

(b) Same conditions, except 8-inch terra cotta arch of side construction.

(c) Same spacing of beams, with expanded-metal arch, type 8.

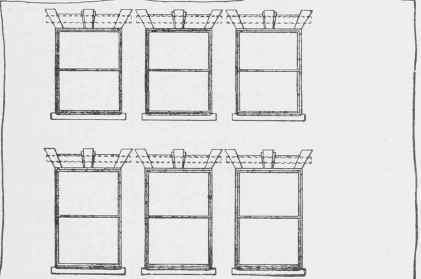

UNTELS TYPE B Fig 91.

(d) Same conditions as above, but expanded-metal arch, type 3, with suspended ceiling.

(e) Beams spaced 7 feet 6 inches center to center. Columbian system, type 2, stone concrete.

Note. In all above cases, partitions are of 3-inch terra cotta blocks, and come only over girders. Clear story height = 10 feet. Give loads for both beams and girders.

8. Required a lintel over opening shown by Fig. 92. Clear span 15 feet, wall 16 inches thick and 50 feet high. No floor or any load carried by wall.

In this type of opening, the narrow piers or columns under the lintels make it necessary to figure the full load of wall, as otherwise the narrow base supporting the heavy overhanging mass of masonry would cause at the piers a thrust that would necessitate continuous tie rods. The full load, therefore, would be 50 X 15 X 1.33 X 115= 115,000 lbs. The effective span of lintel is 16 feet; the capacity of two 18-inch 55-lb. I beams for this span is 117,800 lbs., and these would, therefore, be the required sections.

LINTELS TYPE C. Fig 92.

Required the size of lintel of type B, Fig. 91. Span between centers of bearings, 7 feet. Wall 20 inches thick. Floor load

200 lbs. per square foot. Columns spaced 15 feet from wall.

In this case the piers at side of opening are sufficiently heavy for us to consider the wall over opening as arching, as shown by dotted lines.

Floor load = 200 X 7.5 X 7 = 10,500 lbs.

Wall load =7 X 3.5. X1.67 X115= 4,697 lbs. The full floor load should be provided for. The wall load is not a uniformly distributed load, and moment should be calculated by assuming load between center and end of girder as acting 1/3 the way from the center of the girder.

M of floor load | = | 1/8 x200 x7.5 x7x7x12 | = | 110,200 | inch-pounds. | |

M of wall load | = | 7x3.5x1.67x115 x2.33x12 2 | = | 65,780 | ,, | ,, |

175,980 | ,, | ,, | ||||

The moment in foot-pounds of wall load can be obtained also by the use of the formula M = pl2/ 12 where p is the weight of a square foot of the masonry of the given thickness, and l the span.

If the allowable fibre strain is 16,000, this gives a necessary section modulus of 11.0.

Two 7-inch 9.75-lb. I beams have a total section modulus of 12,0, and would, therefore, be sufficient.

Note. In this calculation the strength of the angle riveted to the channel is not considered in the capacity of lintel.

10. What size of beam will be required to span 19 feet center to center of bearings, and support a uniform load of 1,200 lbs. per linear foot, together with two concentrated loads of 5,000 pounds each? One concentrated load to be applied 7 feet from the left-hand support and the other 8 feet 9 inches from the left-hand support. The allowed fibre stress is 9,000 pounds per square inch.

11. Find the actual stress in extreme fibre of a 12-inch 31.5-lb. I beam spanning 12 feet 6 inches center to center of bearings, and supporting a uniformly distributed load of 23,500 pounds, and one concentrated load of 7,500 pounds placed 4 feet 9 inches from left-hand support.

12. What will be the most economical arrangement of floor beams and girders for carrying a load of 175 pounds per square foot, including weight of floor? Assume floor to be of expanded metal, fireproof construction, and beams spaced not to exceed 6 feet. Under side of floor to carry a plastered ceiling.

13. What size and weight of beam, 23 feet long in the clear between walls, will be required to carry safely a uniformly distributed load of 14 tons, including the weight of beam?

14. What load uniformly distributed, including its own weight, will a 12-inch I beam, 31.5 pounds per foot, carry for a clear span of 23 feet 6 inches, without deflecting sufficiently to endanger a plastered ceiling? Beams rest 12 inches on walls at each end.

15. Calculate by use of Cambria book the moment of inertia about the neutral axis perpendicular to web at center of a 12-inch 31.5-lb. beam.

16. Given a girder loaded as follows: Effective span 28 feet; center load 4,000 lbs.; and a load, 7 feet each side of cen ter, of 3,000 lbs. Required the size of beam such that the deflection will not exceed plaster limits.

17. Given a warehouse 180 feet by 80 feet inside of walls. Columns spaced 18 feet longitudinally and 16 feet transversely. Total load per square foot 300 lbs. Required the necessary sizes of beams and girders.

18. In the above warehouse, what changes in spacing of columns longitudinally could be made to give more practicable sections of beams and girders, and what sizes could then be used?

19. Given a girder loaded as shown by Fig. 93. Allowable fibre stress, 16,600 lbs. per square inch. Required:

(a) The size of single beam girder.

(b) The size of single beam or channel to carry end of girder framing into lintel.

(c) The size of double beam girder.

(d) The size of double beam or channel lintel.

Fig 93.

20. Given a system of overhead beams for an elevator as shown by Fig. 94. Required the size of beams Nos. 1, 2 and 3. Make allowance for shock as previously stated, and observe that when two beams are used together as a girder they must be of the same depth. Allowable fibre stress 15,000 lbs. per square inch.

In all the above problems, unless otherwise noted, use f = 1,600 pounds per square inch.

Continue to: