Anxils

Description

This section is from the book "Spons' Mechanics' Own Book: A Manual For Handicraftsmen And Amateurs", by Edward Spon. Also available from Amazon: Spons' Mechanics' Own Book.

Anxils

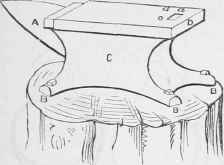

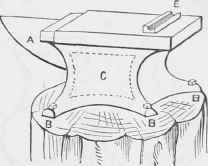

An anvil is an iron block, usually with a steel face, upon which metal is hammered and shaped. The ordinary smith's anvil, Figs. 14 and 15, is one solid mass of metal, - iron in different states; C is the core or body; B, 4 corners for enlarging the base; D, Fig. 14, the projecting end; it contains one or two holes for the reception of set chisels in cutting pieces of iron, or for the reception of a shaper, as shown at E, Fig. 15. In punching flat pieces of metal, in forming the heads of nails or bolts, and in numerous other cases, these holes a of ordinary anvils are not only useful but indispensable. The beakhorn A is used for turning pieces of iron into a circular or curved form, welding hoops, and for other similar operations. In the smithery, the anvil is generally seated on the root end of a beech or oak tree; the anvil and wooden block must be firmly connected, to render the blows of the hammer effective; and if the block bo not firmly connected to the earth, the blows of the hammer will not tell. The best anvils, anvil-stakes, and planishing hammers are faced with double shear-steel. The steel-facings are shaped and laid on a core at a welding heat, and the anvil is completed by being reheated and hammered.

When the steel-facing is first applied, it is less heated than the core. But the proper hardening of the face of the anvil requires great skill; the face must be raised to a full red-heat, and placed under a descending column of water, so that the surface of the face may continue in contact with the successive supply of the quenching fluid, which at the face retains the same temperature, as it is rapidly supplied. The rapidity of the flow of water may be increased by giving a sufficient height to its descending column; it is important that the cooling stream should fall perpendicularly to the face which is being hardened. Heat may escape parallel to the face, but not in the direction of the falling water. The operator, during this hardening process, is protected from spray and smoke by a suitable cover, and by confining the falling water to a tube which must contain the required volume. When an anvil is to be used for planishing metals, it is polished with emery and crocus powders. It is better to be too heavy than too light, and may range from 2 to 5 cwt., according to the work to be done on it. On being tapped with a hammer, it should give out a clear ringing note.

It is generally used with the tail (square) end towards the right hand, and the horn (beak iron) towards the left.

Continue to: