Exercise XII. Rolling Pin

Description

This section is from the book "Wood Turning", by George Alexander Ross. Also available from Amazon: Wood Turning.

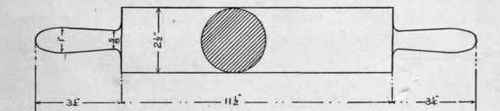

Exercise XII. Rolling Pin

Material: Maple

The work that follows in this manual is, to a considerable extent, a repetition of methods previously given; for this reason the sequence in which the drawings are placed need not be taken into consideration.

The rolling pin shown in Fig. 71 is commenced in the same manner as that given in connection with any piece that is turned up on centers. The stock should be a little longer than the finished article in order to get rid of the center marks on the ends. (The worker will observe that the larger the cylinder, the larger the skew chisel should be, to make the paring cut.)

After the piece is turned to its largest diameter, lay off the distances for the handles and cut off most of the surplus stock with the gouge, after which cut the handles to their largest diameter and then form them by cutting with the gouge, being careful that the side of the gouge does not dig into the end of the body of the roller.

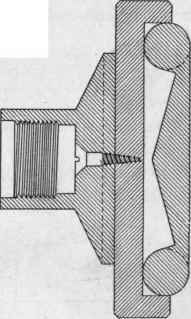

Fig. 70.

Fig. 71.

When all the cutting is done, finish with No. l 1/2, No. 1/2, and No. 0 sandpaper, after which remove from the lathe and finish off the ends of the handles at the bench.

No oil or varnish of any kind is used on this piece of work. A screw eye may be put into the end of one of the handles to hang it up by.

Continue to: