Tools In Common Use For Turning- Steel, Iron And Brass

Description

This section is from the book "Turning And Mechanical Manipulation", by Charles Holtzapffel. Also available from Amazon: Turning and Mechanical Manipulation.

Tools In Common Use For Turning- Steel, Iron And Brass

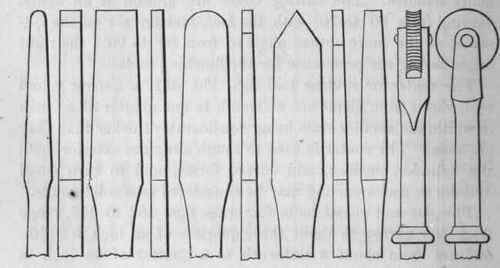

The cutting angles of the tools for turning iron and steel, vary from 60° to 80°. The most general, shown on the face and in profile, figs. 440 to 449, are usually ground at about 60°, and are used direct from the grindstone. Occasionally, for fine finishing cutting, they are set at a slightly increased angle on the oilstone ; for both which processes, see Vol. III. pages 1136 - 1146. The tools are to a great extent used in long or short handles according to their size.

The graver figs. 440. 441. is of square section, it cuts on either side by the portions close to the point of the two adjacent sides of its lozenge shaped bevil; but not by the actual point. For use with the lathe the graver varies from about one eighth, to about half an inch square. The extreme point may be strengthened and saved from the risk of accidental fracture, by just touching it upon the stone, to grind a minute facet at an angle to the principal chamfer. The watch turner uses the side edges and also the point of similar tools of very small size, with the turn bench, fig. 28; these small gravers are also made of lozenge section, to give the rhomboid of the cutting chamfer a more acute form; they are used both for turning and engraving.

The three sides of the triangular tool, figs. 442. 443. are ground flat and to a slight curve in the direction of their length; much like the form of a triangular file, from which the tool is often made. The triangular tool is of about the same dimensions as the graver, the end being also ground off at about the same angle. Unlike the graver, the triangular tool cuts almost exclusively by the three angles of its sides or shaft; sometimes the side edges of its triangular facet are used, but not the extreme point.

Fig. 440. 441. 442. 443. 444. 445. 446. 447. 448. 449.

The flat, round, and point tools figs. 444 to 449, vaiy from very narrow, to about half an inch in width on the face; the smaller sizes being usually of much greater depth than breadth. These tools are used to finish the work after it has been rough turned with the graver; the first, upon the cylinder, surfaces, and convex forms, the round tool for concaves, and the last for grooves, beads, edges and surfaces. The hook or heel tool, figured and its manipulation described, together with some other less general metal turning tools, page 525, Vol. II., is a powerful and very useful tool for iron; its cutting position is precisely analogous to the wood turner's gouge, the hook tool however, being directly supported against the cut by the tee of the rest instead of the hands.

The ordinary hand tools for turning brass, gunmetal and similar alloys, shown upon their faces and in profile figs. 450 to 460, are both narrower and thicker than the corresponding forms used for hardwood; they are mounted both in long and short handles. The cutting edges are ground at an angle, varying from 60° to 70° with the face, and are set on the oilstone, at the more obtuse angle of from 80° to 90°; the right angle having the preference for the finishing tools.

The router or routing tool figs. 450. 451, a narrow round tool, varies from about one sixteenth to one quarter of an inch in width, the smaller sizes being considerably thicker than they are wide. The router is used to rough away the exterior upon the cylinder, surface, and curved forms, and to turn small hollows or concaves, and may be considered as a solid gouge.

The flat and round tools for brass, figs. 452 to 456, range from very narrow to about three quarters of an inch in width, and are from about a sixteenth to a quarter of an inch in thickness; they are ground and sharpened to cut both upon their sides and ends, and are used subsequently to the router to smooth and finish the turned surfaces. The point tool figs. 456. 457, is of similar dimensions and is used for surfaces, edges, beads, and grooves; sometimes the extreme point is slightly rounded and the tool used to replace the router. The square tool, fig. 458, frequently ground out of an old square file, has all its four faces and angles alike, the sides like those of the triangular tool for iron being very gently curved lengthwise. The square tool is used upon the surface, and'upon the internal cylinder, when it is usually supported on the armrest. Strong, narrow, right side tools, fig. 390, ground to the appropriate cutting angle for brass, are also much used for internal work, and the hardwood parting tool, fig. 389, may also be employed.

The milling tool, figs. 459. 460. consists of a small, solid, hardened steel wheel, from about half to three quarters of an inch in diameter, generally less than a quarter of an inch in width but occasionally very much wider, revolving freely on a steel axis in an iron stem; the edge of the wheel may be flat, concave or convex as required, and is impressed or cut with fine or coarse lines or devices forming a pattern. The milling tool is held against the revolving work, with which it is placed in forcible contact by pressure and by lowering the handle ; it imprints its pattern partly by compression, and partly by nibbling away or abrading the sides of the indentations it forms on the work. The compression exerted first causes a series of slight indentations somewhat like the teeth of a cogwheel, but the teeth or ornament upon the milling tool not being of a form admitting of purely rolling contact, a scraping or abrasive action then commences; this secondary action being enhanced by the circumstance, that the work and the tool usually travel at very different angular velocities, the one being generally of much larger diameter than the other.

Fig. 450. 451. 452. 453. 454. 455. 456. 457. 458. 459. 460.

In using the milling tool the pressure is at first given moderately, and then gradually increased until the perfect pattern appears, which arrives so soon as the action has slightly, but sufficiently reduced the diameter of the work. The milling tool is then withdrawn as its further use would unduly reduce the diameter upon which it operates, and if continued, blurr or disfigure the pattern. Similar milling tools are used either upon iron or brass; upon the latter they will endure a considerable amount of work but they are quickly worn out upon iron or steel; separate tools are therefore reserved for iron and for brass, as a worn tool makes but little progress even upon the softer metal. The milling tool is sometimes applied to wood, much of the German toy turnery from the Black Forest, being very effectively ornamented with it. It is also employed in this country for ornamenting porcelain and terra cotta; the wheel then called a " runner," is an inch or an inch and a half in diameter, and is made of hardwood.

Continue to: