Key-Hole And Pruning Saws. Part 6

Description

This section is from the book "Turning And Mechanical Manipulation", by Charles Holtzapffel. Also available from Amazon: Turning and Mechanical Manipulation.

Key-Hole And Pruning Saws. Part 6

The Continental frame-saw used abroad for the general purposes of carpentry and cabinet-making, is shown in fig. 708; in the largest of these the blades are about three feet long, one and a half to three inches wide, and very thin; and others as small as half those sizes are also used. The wooden handles, h h, shown also detached and of twice the size at h', have cylindrical stems, which pass through the end pieces; they are cut through longitudinally for admitting the sheet iron T form clamps, which are each held by a rivet passing through the handle outside the frame; the blade is fastened between each pair of clamps by a pin or screw.

The handles being cylindrical, the saw can be placed at all angles with regard to the frame, and may therefore be employed for cutting off pieces of indefinite length, provided they do not exceed the width from the blade to the stretcher, which latter is forked at the extremities to embrace the cross pieces, and this allows it to be shifted nearer to the string when required for wide pieces. Before using the saw it should be observed to place the blade exactly in a plane, or out of winding.

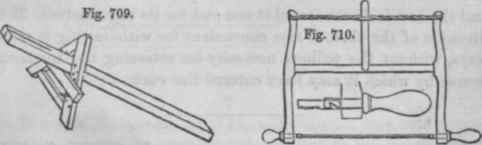

Most of the works performed in England with the hand-saw, the tenon, dovetail, and similar saws, are abroad accomplished with frame-saws of various sizes; the pieces are mostly fixed, either to or upon the bench, and the contrivance for holding long works, shown in fig. 709, is also general on the Continent.

The work to be sawn is passed through the triangular opening in a wooden frame, nearly in the form of the letter A; when the frame and work lie at an obtuse angle, they constitute a three-legged stool. The upper edges of the board become wedged fast in the angular sides of the triangle, and the lower side of the board rests on the cross piece of the supposed letter, which may be placed at various heights, according to the size of the work, as it rests on two moveable pegs. In sawing small works, the man rests his knee on the work near the top of the frame, and the board is changed end for end when sawn through half its length. Triangular frames, with various modifications, are also commonly used abroad instead of the saw-pit; but our own occasional method, namely, a pair of trestles about six feet high, is much better, as each of the sawyers is then far more favourably situated than when the timber is placed aslant.*

The turning-saw, or siveep-saw, fig. 710, which is also called the frame-saw, or bow-saw, resembles fig. 708, except in its smaller size and greater proportionate width of frame; this will be apparent, as the figures are drawn to the same scale.

Its handles have always cylindrical wires that pass through the end rails: the wires are sawn diametrically to admit the saw blade, and are drilled transversely for the pins; frequently the one handle has an undercut notch, as represented on a larger scale, so that the saw may be removed sideways from the one handle, and allowed to move as on a joint upon the other, a provision that is often turned to a useful account.

In using the bow-saw the work is mostly fixed vertically, and therefore the blade is used horizontally; but the frame is placed at all angles, to avoid the margin of the work, and it is frequently necessary to twist the handles or pins during the cut, to modify the position of the frame. It often happens that the cut has to be commenced from a hole or aperture, in which case the tension of the blade is relieved by a turn of the stretcher, and the saw is disconnected at one end for its introduction. The disunion of the blade is also convenient for withdrawing it sideways, without the tedious necessity for retracing the tortuous course by which it may have entered the work.

It still remains to notice those saws, the frames of which may be considered to be slightly flexible, and to form the three sides of a rectangle. The ivory-saw, which has been already figured and described at pages 146 and 147 of the first volume, is the largest of this kind, and the full particulars have been there given, of its use in the preparation of ivory. Sometimes the frames of saws for ivory are made of iron, and without the adjusting screw clamp; the frame is then sprung inwards by means of a long hook whilst the saw is inserted.

* These and relative matters are fully described and figured by A. R. Emy, in his Traite de l' Art de la Charpenterie. Paris, 1837. Plates 2 to 11.

The smith's frame-saw, fig. 711, is nearly a copy of the saw last referred to, and it almost always possesses a screw and nut for stretching the blade.

The mode of using the saws, for metal, is the reverse of that in saws for wood; as for metal, the motion should be slow, and pressure somewhat considerable, and the necessity for each of these conditions increases with the hardness of the material. The saw is almost invariably moistened with oil or tallow-grease, and in the back strokes the pressure on the blade is discontinued, but the saw is not raised from the bottom of the notch; in this respect the action resembles that of the file.

The smith's frame-saw is the common instrument used in metal works for the removal of pieces that are in excess, and in many cases instead of the whole substance being cut through, a notch is made on two sides of the work, and the center part is broken. This saw is also used for making notches and grooves, much the same as in cabinet-work; but except in small works, preference is given to the figuration of materials by casting, forging, and other modes already described.

The side frame-saw, fig. 712, although far less common, is greatly preferred by some workmen; thus, in making the joints of drawing instruments, much depends on the correct use of the frame-saw, by which the notches are made for the reception of the steel plates used in the joints, and fig. 712, in which the blade is more immediately under observation, is preferred to fig. 711. For routing out the concave part, a saw like fig. i is used, and inserted a little way into the joint, until the holes in the joint and tool are sufficiently opposite to admit the end of a taper pin; the joint-saw or router is then moved to and fro, and as the concavity is cut away, the pin is set forward until its cylindrical part causes the two holes to be exactly opposite, and then the work is completed.

Continue to: