Turned Tobacco Pipes

Description

This section is from the book "Turning And Mechanical Manipulation", by Charles Holtzapffel. Also available from Amazon: Turning and Mechanical Manipulation.

Turned Tobacco Pipes

These are made from many of the softwoods, their roots and burrs, pear and cherry tree are the more usual; from some harder kinds, and from the so-called "briar root," the last name being a corruption of the French Bruyere, the Erica Arborea, a native of Southern Europe ; from cocoa and other hardwoods, and from meerschaum. The bowl and stem are turned in one solid, the method followed is alike for all, the tools employed being those ordinarily used for soft and hardwood according to the material. This is first roughed out with the saw from parallel pieces, to the form of fig. 764, and if made from softwoods, the blanks require to be laid aside and allowed time to season.

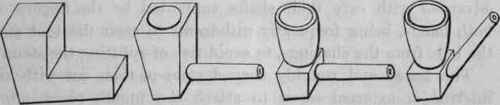

Fig. 764. Fig. 765. Fig. 766. Fig. 767.

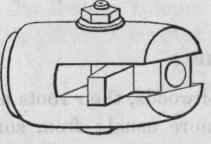

The stem and bowl are turned at two chuckings, the short rectangular portion left at their junction, figs. 766, 767, being subsequently reduced to form by paring and filing. The interior of the bowl is turned first, with the blank held across the gap of the wood spring chuck, fig. 768; this is similar in character to the upright chuck, fig. 318, but to meet more constant use it is stronger and the jaws are closed by an iron screw bolt and nut turned by a key. The blank is then replaced in the chuck at right angles, the shaft adjusted to the center, that the corners of the stem may be removed with the gouge, leaving it strong for the boring, and the extremity is turned true, faced and centered. The delicate, long spoon bit for softwood, and the slender pipe bit used for boring the stems in hardwood, and their manipulation, have been described in the elementary chapters; meerschaum stems may be freely bored with either tool, or with the wire drill flattened and ground to a point, which last is used in boring amber. All the drills are advanced with care their shafts supported by the fingers of both hands, being frequently withdrawn to clear the tool and the hole from the shavings, to avoid risk of splitting the stem.

Fig. 768.

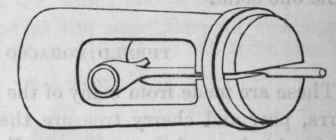

Fig. 769.

The bored and roughly shaped stem is then cut with an internal or external screw to attach the mouth piece, after which it is finished externally, the turning being carried as far as possible towards the bowl, fig. 765; the stem supported against the thrust of the tool by the left forefinger placed around it from below. The spring chuck, fig. 769, is employed for turning the more delicate stems, for alterations when the bowl has been finished, and for meerschaum. The interior is largely cut away to render the sides very elastic and to allow space for the bowl; they are closed on the work by a ring pressed on by hand, the ring sometimes receiving light blows from the end of the tool handle, on the one or the other side of the face, to adjust the work to run true. Slender stems are projected and turned a short portion at a time, that close to the bowl held by the chuck, being finally reduced to shape with the file. Oval and flattened stems, are turned to the larger diameter of their section, and then worked down to form with the file.

The partially completed pipe is then mounted by the aperture in the bowl, upon the solid wood arbor chuck, fig. 770, to turn the exterior; the form is shaped as far as convenient towards the stem, the tool being advanced at a horizontal angle to prevent its shaft or the hands, encountering the stem as that revolves. When the stem is at less than a right angle, fig. 767 a longer arbor chuck is employed, that the rest and hands may be well to the left to project the tool at a sufficient angle. The rectangular portion left at the junction by the turning, is pared, or rasped away, and then filed down to shape, glass papered and polished, upon the wooden filing block, fig. 771. This is variously grooved upon the surface, and may be held in the vice, but is more frequently turned to a stem below, to fit the socket of the hand rest. The pipe held on a wooden arbor inserted in the bowl as a handle, is twisted round on the filing block when filing the bowl, and the bowl itself is held in the hand when working on the stem, the turned portions serving as a guide for the curved lines filed to connect the two.

Fig. 770. Fig. 771.

The blanks for meerschaum pipes are sawn from the irregularly formed masses in which the material is imported, and when soaked in water for about twenty-four hours, are turned and shaped after the same method as that described for wood; most of the chucks and arbors being covered with cloth, or one or two thicknesses of flannel, to prevent damage to the soft material. The ordinary soft wood chisel is used wherever possible to turn the bowl and stem, but small round, flat and point tools, ground to a single, and equally acute bevil, are also employed. The tools are used as in turning the softest woods, and the meerschaum cuts or pares away with extreme readiness, but being also homogeneous, it is of easy management under the turning or carving tools.

The end of the meerschaum stem is bored for about an inch in depth, sufficiently larger than the bore of the pipe to admit a slender wooden tube, the short projecting end of which is cut with a screw to attach the amber mouth piece. The piece of amber, roughed out with the saw and rasp, is mounted in fig. 769, to be bored, hollowed and cut with an internal screw; these portions and the exterior, being turned with any of the smaller hardwood tools; some preferring to warm the amber over a lamp or gas, before commencing. The external form may be flattened with the file, the marks from which are then removed with fine glass paper, and the amber is polished with rottenstone and oil upon a piece of flannel, or upon a flannel covered buff wheel, finishing with the same powder dry.

Meerschaum pipes turned and filed to shape, have all file marks removed with nearly worn out glass paper or dutch rush, and are then further polished upon flannel covered buff wheels running in the lathe, charged with a fine white powder imported from Vienna, and known as "Calsch." The composition of this powder is a trade secret, but it appears to be a natural product principally composed of carbonate of lime, as indeed its name almost implies; it is received in the form of small pieces, a few of these are taken, slightly sprinkled with water and allowed to remain for a day or two, when they crumble into a fine and perfectly even powder, fit for use.

The round edge and the flat face of the buff are both employed, the latter for the turned portions of the bowl and stem, which are held radially and twisted round upon it by the fingers. The buff however is very sparingly used, otherwise it is too active for the soft material; the polishing is then continued by friction with the powder applied on a piece of flannel. Subsequently the pipes are rubbed with flannel and melted white wax; in which latter, their apertures being temporarily stopped, they are sometimes immersed.

Continue to: