Fastenings

Description

This section is from the book "Spons' Mechanics' Own Book: A Manual For Handicraftsmen And Amateurs", by Edward Spon. Also available from Amazon: Spons' Mechanics' Own Book.

Fastenings

With regard to fastenings, the figures already given show several applications. Wedges should be split or torn from the log, so that the grain may be continuous; or if sawn out, a straight-grained piece should be selected. Sufficient taper should be put on to give enough compression to the joint, but too much taper would allow the possibility of the wedge working loose. For outside work, wedges should be painted over with white-lead before being driven, this not being affected by moisture, as glue would be. In scarf joints the chief use of wedges is to draw the parts together before the bolt holes are bored. Keys are nearly parallel strips of hard wood or metal; they are usually made with a slight draft, to enable them to fit tightly. If the key is cut lengthways of the grain, a piece with curled or twisted grain should be selected, but if this cannot be done, the key should be cut crossways of the log from which it is taken, and inserted in the joint with the grain at right angles to the direction of the strain, so that the shearing stress to which the key is subject may act upon it across the fibres. In timber bridges and other large structures, cast-iron keys are frequently used, as there is with them an absence of all difficulty from shrinkage.

Wooden pins should be selected in the same way as wedges, from straight-grained, hard wood. Square pins are more efficient than round, but are not often used, on account of the difficulty of forming square holes for their reception. Tenons are frequently secured in mortices, as in Fig. 4S9, by pins, the pins being driven in such a manner as to draw the tenon tightly into the mortice up to its shoulders, and afterwards to hold it there. This is done by boring the hole first through the cheeks of the mortice, then inserting the tenon, marking off the position of the hole, removing the tenon, and boring the pin-hole in it rather nearer the shoulders than the mark, so that when the pin is driven it will draw the tenon as above described. The dowelled floor shown in Fig. 50S gives another example of the use of pins.

Nails, and their uses, are too well known to need description; it may, however, be well to call attention to the two kinds of cut and wrought nails, the former being sheared or stamped out of plates, and the latter forged out of rods. The cut nails are cheaper, but are rather brittle; they are useful in many kinds of work, as they may be driven without previously boring holes to receive them, being rather blunt pointed and having 2 parallel sides, which are placed in the direction of the grain of the wood. The wrought nails do not easily break, and are used where it is desired to clench them on the back to draw and hold the wood together. Spikes are nearly of the same form as nails, but much larger, and are mostly used for heavy timber work. Treenails are hard wooden pins used in the same way as nails. In particular work, with some woods, such as oak, they are used to prevent the staining of the wood, which would occur if nails were used and any moisture afterwards reached them. Compressed treenails are largely used for fixing railway chairs to sleepers, as they swell on exposure to moisture, and then hold more firmly. Screws are used in situations where the parts may afterwards require to be disconnected.

They are more useful than nails, as they not only connect the parts, but draw them closer together, and are more secure. For joiners' work the screws usually have countersunk heads; where it is desired to conceal them, they are let well into the wood, and the holes plugged with dowels of the same kind of wood, with the grain in the same direction. For carpenters' work the screws are larger and have often square heads; these are known as coach screws. The bolts, nuts, and washers used in carpentry may be of the proportions given in the following table; -

Thickness of nut............ = 1 diam. of bolt.

„ head .......... = 3/4

Diameter of head or nut over sides .. .. = 13 "

Side of square washer for fir ...... = 3 1/2 „

" .. oak...... = 2 1/2

Thickness of washer.......... = 1/3 "

The square nuts used by carpenters are generally much too thin; unless they are equal in thickness to the diameter of the bolt, the full advantage of that diameter cannot bo obtained, the strength of any connection being measured by its weakest part. The best proportion for nuts is that of a Whitworth standard hexagon nut. A large square washer is generally put under the nut to prevent it from sinking into the wood and tearing the fibres while being screwed up; but it is also necessary to put a similar washer under the head to prevent it sinking into the wood. This is, however, often improperly omitted.

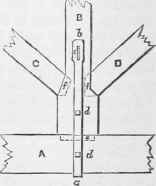

Straps are bands of wrought iron placed over a joint to strengthen it and tie the parts together. When the strap is carried round a piece, and both ends are secured to a piece joining it at right angles, as in a king-post and tie-beam, it is known as a stirrup, and is tightened by means of a cotter and gib keys, as shown in Fig. 510. When straps connect more than two pieces of timber together, they are made with a branch leading in the direction of each piece; but they are usually not strong enough at the point of junction, and might often be made shorter than they are without impairing their efficiency. Sockets are generally of cast iron, and may be described as hollow boxes formed to receive the ends of timber framing.

With regard to the use of glue for securing joints, it has been found that the tensile strength of solid glue is about 4000 lb. per sq. in., while that of a glued joint in damp weather is 350-360 lb. per sq. in., and in dry weather about 715 lb. The lateral cohesion of fir wood is about 562 lb. per sq. in., and therefore in a good glue joint the solid material will give way before the junction yields.

Continue to: