Filtering Water

Description

This section is from the book "American Library Edition Of Workshop Receipts", by Ernest Spon. Also available from Amazon: American Library Edition Of Workshop Receipts.

Filtering Water

(a) A new filter, invented by Dr. William Paulson, of Loughborough, is shown in Fig. 24. It has been designed with a view to use an entirely inorganic, and at the same time a durable and powerful germicide as filtering medium, which, while not a mere strainer, can be easily and cheaply renewed. The basis of the filtering medium is coke, the power of which is increased by a silicate dissolving with a clean surface sufficiently to destroy germs, but not to make the water unpalatable. The method of renewal adopted is to place the filtering-jar in a hot oven ranging from 400° to 600° F., a temperature at which all absorbed impurities are charred. The flat vapid taste of filtered water is obviated by restoring to it a small proportion of carbonic acid gas. This is done by using as a lid a flat bottle With a straw hula in the side to allow the escape of gas. A small quantity of acid and soda and a glass of water are then placed in the bottle, and the result is a sparkling and palatable filtered water.

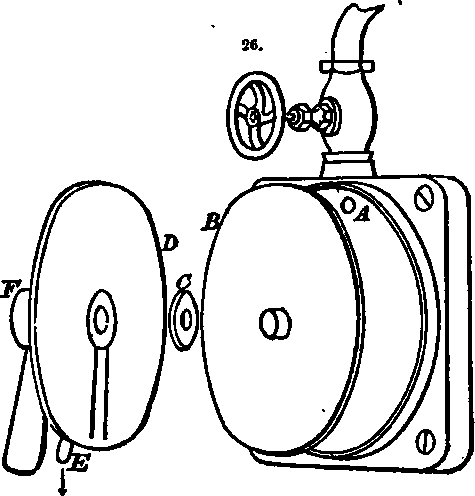

(6) The Johnson filter (Figs. 25, 26) is both mechanical and chemical, and is applicable to both domestic and industrial uses. Fig. 25 shows the domestic style, and Fig. 26 fires the internal arrangement of it. The water enters through the pipe shown at the upper part of the engraving, traverses a disk of prepared carbonised paper, B, and reaches a metallic plate, D, from whence it flows off at E. This plate D, is pat in place by means of a screw, F. The disk of filtering paper may be changed with the utmost ease, and the operation may be performed by the most inexperienced domestic As the entire apparatus is of iron, there is no danger of breakage. The domestic style shown is the smallest sized one. It is constructed in two other styles in which the filtering disks are are suposed, so that several of them operate at one and the same time, and time give a much larger quantity of filtered water within the same period. By thus superposing the Altering parts, the inventor has been enabled to construct a large industrial model that is much used in breweries and that is capable of furnishing mora than 130,000 gal. of filtered water per day. In the small apparatus the filtering material is a special paper composed solely of purified cotton fibres and bone-black freed from all phosphates.

In the large filters, which resemble barm presses and are managed in the same way, paper is used in conjunction with specially prepared cloth. {La Nature.) (c) The Mallie- filter (Figs. 27, 28) utilises the pressure of the city water to force the latter to ooze through porcelain, which retains in its close and imperceptible pores all organic germs. His apparatus consists of a porcelain filter, properly so called, which the water enters under pressure through a tube affixed to a cock. This filter is inclosed in a thick earthen vessel, which is affixed to a metallic support by a bayonet catch, and which serves to protect the porcelain and collect the purified water. The apparatus is made tight through rubber washers of circular or elliptical section, which take the exact impressions of the grooves in the upper part of the porous vessel and the adjacent faces of the socket and cap of the apparatus. This forms a very tight joint without exerting a stress that might break the neck of the porous vessel. The lower part of the entrance tube is narrowed, and serves as a seat for a conical valve carried by a rod that rests upon the bottom of the filtering vessel. In case of a breakage of the latter, the valve closes.

Owing to the automatic operation of this safety apparatus, no accidental flooding and no discharge of unfiltered water is to be feared. The cup constitutes a true reservoir that contains a certain quantity of compressed air, which, thanks to its elasticity, tends to prevent breakages that might occur through the ram strokes of the water under pressure. Besides, the air dissolves in the liquid, and so the latter, on making its exit from the filter, is charged with minute globules of it; hence the name "aerifilter "that the inventor has given the apparatus. Since the action of filtration is exerted from within outwardly, salts of various kinds may be put into the interior (so as to obtain artificial mineral waters), or special materials for decolorising liquids, or, finally, ice (even impure) for cooling the water in summer. A simple apparatus is capable of filtering 9-10 gal. per day, according to the pressure of the water. By modifications in its proportions and construction a larger quantity of water might be filtered.

Paulson's filter.

Johnson's filter.

Johnaon's filter.

Laboratory Methods

(a) Viscid liquids, such as are obtained in processes of artificial digestion, may be filtered, according to Fresenius, by the aid of finely picked asbestos fibre. Not only is. the filtration of such fluids exceedingly slow, but the filtrate often passes turbid even through paper of the closest texture. To filter such a fluid, Fresenius advises to dilute with water, add some recently ignited asbestos, and shake the mixture vigorously. After about 12 hours the suspended matters will have subsided, leaving the supernatant-liquid perfectly clear. This is to be siphoned off, and the residue to be washed once or twice by decantation, and then passed through a glass funnel the neck of which contains a pellet of asbestos. If the first part of the filtrate runs off cloudy, it is returned to the funnel until it passes clear.

(b) A funnel for filtration in absence of air, is shown in Fig. 29. The funnel has a cylindrical rim 1-2 cm. high, covered with a lid provided in the centre with a neck. Into this fits a cork and bent glass tube. The funnel is fitted into a filter flask, which has a side tube. By connecting the tube of the funnel with that of the flask by a piece of rubber tubing, the exterior air is excluded.

Continue to: